BESTBATH SHOWER AND TUB

www.bestbath.com

|

800.727.9907 723 Garber Street

|

Caldwell, ID 83605

1034

ACCESSORY INSTALLATION AND

PRODUCT MAINTENANCE

TABLE OF CONTENTS

Seat and Grab Bar 2

Soap Dish – Surface Mount 3

Soap Dish – Corner Mount 4

WaterStopper – Standard Application 5

WaterStopper – Corner Application 6

Semi-Permanent Threshold Adaptor 7

Curtain and Rod 8

Standard 26" Glide Bar 9

Flange Trim Kits:

for Wing Wall 10

for Remodel 11

with Reveal 12

for New Construction 13

Window Trim Kits:

up to 37" width 14

up to 73" width 15

Cleaning and Maintenance

Recommendations 16

This guide includes installation instructions for Bestbath accessory

products plus recommendations for cleaning and maintaining your

Bestbath tub or shower.

These instructions are also available at: www.bestbath.com/resources

and in video format on youtube.

For Bestbath warranty information, visit www.bestbath.com

NOTE: This complete set of installation instructions is shipped with every Bestbath

accessible unit. Not all products covered here will necessarily apply to your purchase.

Page 2

1075

Seat and Grab Bar

•

Folding seat, with or without swing-down legs

•

Grab bar

•

Grab bar wall flanges (2)

INSTALLATION INSTRUCTIONS

•

Tape measure

•

Marker or pencil

•

Screw gun

•

7

⁄32" bit

•

1

⁄4" bit

•

#2 Phillips bit

•

5

⁄16" socket

•

100% silicone

•

Caulk gun

•

#10x 1

1

⁄4" Phillips-head stainless

steel sheet metal screws (7)

•

#10-32 x 1

1

⁄4" stainless steel cap

screws (2)

•

#10-32 T-nuts (2)

If seat or grab bar location is predrilled:

With some models, the seat or grab bar location may be pre-

drilled, just through the first layer of fiberglass. In those cases, do

not drill any further into the wood. Simply apply silicone as shown

and attach using the supplied fastener.

If seat or grab bar location is NOT predrilled or marked:

1. The seat should be installed 18" above the floor. Install the

grab bar 34" above the floor to ensure that the seat will not

swing up and hit the grab bar (Figure 1). Use a pencil to mark

the seat flange and bracket hole locations on the wall.

2. Make sure the spot where the seat or bar is being attached

has plywood backing. To test for plywood, barely drill through

the fiberglass with a

7

⁄32" bit, just until you see a few wood

shavings. Do not pre-drill all the way into the wood. If you

cannot locate any wood, see Installation Notes below.

3. Apply a half-circle of silicone to the flanges above the two top

screws and around the lower hole (Figure 2).

4. Install the seat/bar with the screws, making sure you can feel

resistance from the plywood as the screws go in (Figure 3).

5. Adjust the feet to ensure that all four are touching the floor

and then tighten the jam nuts. Failure to do so may result in

injuries to the user and/or damage to the shower that will not

be covered by the warranty.

Installation Notes:

•

When installing the grab bar, at least one of the three flange

screws in each flange must hit wood. If it does not, try drilling

an additional test hole in the flange closer to the other holes.

Alternatively, use a suitable blind fastener (toggler or WingIts

®

).

•

Do not install a fold-down seat without swing-down legs unless

at least one of the three flange machine screws (with a T-nut)

is attached to wood backing. If your unit does not have wood

backing where you need it, install 2x6 blocking between the

studs to provide suitable attachment.

•

If you cannot locate or add suitable backing, you can install grab

bars and seats (with swing-down legs only) using a WingIts

®

brand fastening system, also available from Bestbath.

•

Loads in excess of 250 lbs. always require a seat with

swing-down legs.

SUPPLIES AND TOOLS NEEDED:

HOW TO INSTALL

ACCESSORY KIT CONTENTS:

WingIts is a registered trademark of WingIts Innovations, LLC.

Silicone

Figure 2

#10 x 1

1

⁄4" stainless Phillips-head

sheet metal screw (only for seats

with legs).

Fiberglass laminate

Plywood backing

Figure 3

Make sure seat

will clear bar

34"

18"

FOLDING SEAT WITH SWING-DOWN LEGS

Figure 1

Page 3

INSTALLATION INSTRUCTIONS

SUPPLIES AND TOOLS NEEDED:

ACCESSORY KIT CONTENTS:

Trace line

Tape

HOW TO INSTALL

1. Hold the soap dish level, at the desired location on the tub/

shower wall, and trace around it with a pencil.

2. Tape off around the traced area as shown at right.

3. Clean both the area within the tape and the contact edge of

the soap dish with a solvent such as alcohol or acetone.

4. Scuff the area with sandpaper, then blow or brush off sanding

dust so surface is clean for application of epoxy adhesive.

5. Mix epoxy according to instructions on the package.

6. Spread adhesive on the back of the soap dish and press it into

position. Hold it there while you use your free hand to quickly

remove the masking tape and the excess adhesive on it.

7. Continue holding the soap dish in place for a few minutes

more until you feel it has set up enough to remain adhered.

Alternatively, secure it with hot-melt glue while the adhesive

cures.

8. When the adhesive has cured to the point of being fairly solid

(approx. 5 minutes), apply a small bead of silicone where the

soap dish and the shower wall meet.

INSTALLATION INSTRUCTIONS

1076

Soap Dish (Surface Mount)

•

Sandpaper

•

Cleaning solvent (alcohol or acetone)

•

Masking tape

•

Rags or paper towels

•

Tape measure

•

Hot-melt glue gun (optional)

•

Soap dish

•

2-part, 5-minute epoxy

•

100% silicone

Page 4

INSTALLATION INSTRUCTIONS

ACCESSORY KIT CONTENTS:

HOW TO INSTALL

1. Hold the soap dish level (or slightly tipped forward) at the

desired location on the tub/shower wall. Using a pencil, trace

the edge on one side of the dish (Figure 1).

2. Hold the dish on the line you drew and install the screws on

that side. Screws should be snug but not tight (Figure 2).

3. Hold the dish level and trace the opposite edge (Figure 3).

4. Hold the dish on the line you drew and install the second set of

screws. Then tighten all four screws (Figure 4).

5. Apply silicone sealant along the sides from the top but leave

the corner open to allow drainage (Figure 5).

1082

Soap Dish (Corner Mount)

•

Soap dish

•

100% silicone

•

Screws (4)

SUPPLIES AND TOOLS NEEDED:

•

Pencil

Leave back corner free of

caulk to allow drainage.

Figure 5

Apply silicone along

top edge of sides.

Figure 1

Hold dish level and trace

one edge with a pencil

Figure 3

Trace opposite

edge

Figure 2

Install screws snugly,

but not tight

Figure 4

Install two remaining screws,

then tighten all four screws

Level (not supplied)

Level (not supplied)

INSTALLATION INSTRUCTIONS

1077

Page 5

(Standard Application)

•

Alcohol wipes (2 included in kit)

•

E-6000 adhesive (included in kit)

•

Pencil

•

Scissors or utility knife

•

Straight edge

NOTE: Adhesion may be poor on surfaces (tile) treated with

silicone-based sealers. To test adhesion, peel back about 1"

of the WaterStopper backing, press adhesive area to surface

where it will be installed and leave it overnight. Check the

test sample by pushing sideways as shown at right. If it has

adhered sufficiently, pull straight up and proceed with the

installation. If it has not adhered, more agressive chemical

stripping may be necessary.

2

1

⁄4" radius

3

⁄8" radius

Clean surface with supplied alcohol wipe

(SURFACE MUST BE DRY).

1

Use a pencil to draw the outline of the endcap on the

shower.

3

Draw a line with a straight edge that connects the two

marks from Step 5.

6

When you reach the arrow mark at the other end, cut

off any excess material and firmly press the end to

the floor. Move along the length pressing firmly

down on both sides of the WaterStopper.

9

Choose the end caps that fit your unit. Without removing adhesive backing, place endcap so it is level at the curb edge and

inside the shower front. Note the distance from the front of the shower for second endcap.

2

Mark the floor at the embossed arrow.

4

Peel off about 4" of the adhesive backing from

the WaterStopper and stick the corner at the two

intersecting marks.

7

Peel the backing off the self-adhesive tape on the

endcaps.

10

Press the endcaps down inside the drawn outline. Make sure the upright portion of

the WaterStopper is slotted properly into the endcap. Use the second alcohol wipe

to remove any excess E-6000 adhesive and the pencil marks.

12

E

6

0

0

E

6

0

0

0

Apply E-6000 adhesive on the edge around the bottom

and inside the front slot.

11

The WaterStopper will be ready for use after four hours. The WaterStopper combined

with a heavy duty, weighted curtain offers one of the best water retention system

available.

13

Mark the floor at the edge of the underside indent at the

open end of the endcap.

5

Using the line as your guide, continue to peel off the

backing as you gently stretch the WaterStopper and stick

it down along the line you drew.

8

Repeat Steps 2 through 5 with the second endcap at the other end of the shower.

Too highToo low

KIT CONTENTS AND SUPPLIES:

INSTALLATION INSTRUCTIONS

Page 6

(Corner Application)

1078

To begin, refer to Steps 1 – 6 on the WaterStopper Standard Application instructions.

Lay the WaterStopper along the front

of your shower, leaving equal excess at

each end.

Extend your pencil mark onto the vertical

surface.

This is an example of a cut for a 90°

corner shower.

With one finger or thumb in the inside pit

of the cut, press the WaterStopper down

onto the shower.

Mark the WaterStopper nearest the

corner with a pencil.

From the angle templates at bottom of

page, cut out the one that matches the

angle of your shower.

Slice the backing about 6" on either side

of the cut out. DO NOT

cut through the

adhesive strip or the rubber (see step 9).

Hold the center cut down with one hand

and use the other to stretch tight and

stick the exposed section of the adhesive

down to the corner of your shower.

Follow Steps 3-10, using a scrap piece of

wood or other hard surface between the

shower floor and the WaterStopper to make

your cut. Remove backing between cuts.

Place the template on the WaterStopper

with the arrow pointing toward your mark

and the parallel lines (=) flat against the

outside edge. Trace the template.

Remove this section of the backing.

Run your thumbs or fingers along the

outside bend, sticking the curled section

down.

Holding the first angle firmly, pull tight and

stick second corner down while making

sure the front is straight. Continue with

Step 12.

Use your razor knife to cut out the traced area.

Make sure to start your cut on the vertical

surface. If the WaterStopper does not fully bend

to your angle, cut further into the vertical surface.

DO NOT make cuts on your shower surface.

Bend the WaterStopper to your corner

angle. Make sure that the outer edge

curls up rather than down.

Your corner is finished. Continue with

Steps 9-11 on the WaterStopper Standard

Application instructions (FORM 1077) to

add end caps and complete installation.

1

3

7

11

2

4

.

fi

12

13

90º

90º

90° corner

Neo Angle

8

12

N1

5

9

13

N2

6

10

14

Scrap

wood

For Neo-Angle Showers

Angle Templates:

90º

90º

90° corner

Neo-Angle

After Step 2, use the 45° template and refer to Steps N1 and N2 below.

Page 7

INSTALLATION INSTRUCTIONS

ACCESSORY KIT CONTENTS:

HOW TO INSTALL

1. Put the adaptor in place and trace a pencil line around it on the

shower bottom (Figure 1).

2. Place a

1

⁄4" bead of silicone just inside the pencil line.

3. Carefully put the threshold in position (Figure 2).

4. Smooth out the excess silicone with a wet finger. A strip of

masking tape, positioned

1

⁄4" from the pencil line on the shower

and

1

⁄4" from the edge of the adaptor, will help ensure a smooth

edge and make excess silicone easier to remove (Figures 2

and 3).

5. Remove the masking tape and touch up with a wet finger to

smooth and feather edges of the silicone.

6. Do not disturb for 12 hours.

To remove the adaptor:

1. Holding the blade flat, carefully cut through all the silicone with

a utility knife.

2. Pivot the threshold sideways into the shower and pull it up.

3. Carefully remove the silicone with a single-edged razor blade

and Goof Off

®

Remover or other caulk remover (available at

most hardware stores).

SUPPLIES AND TOOLS NEEDED:

•

Pencil

•

Masking tape (optional)

•

Threshold adaptor

•

100% silicone

1079

Semi-Permanent Threshold Adaptor

Part Numbers TAS, TASW, and TASM

Masking

tape

Figure 3

1

⁄4"

1

⁄4" bead

of silicone

Masking tape

on shower wall

and pan.

1

⁄4"

Figure 2

Goof Off is a registered trademark of W.M. Barr Company Inc.

Pencil line

Figure 1

Threshold adapter

Page 8

INSTALLATION INSTRUCTIONS

ACCESSORY KIT CONTENTS:

HOW TO INSTALL

•

Cut the curtain rod to the correct length based on whether it will

be installed on the walls of the shower or on the walls above the

shower unit.

•

Use screws to attach a bracket at the right level on each side of

the shower unit (or wall above).

•

Curtain rod

•

Curtain rod bracket (2) with screws

1080

Curtain and Rod

Plastic curtain

rod bracket

Curtain must be

74" long

(sold separately)

74"

75"

Curtain rod

Curtain ring

(sold separately)

Position horizontally

so the curtain hangs

against the inside of

the WaterStopper.

2"

Page 9

INSTALLATION INSTRUCTIONS

ACCESSORY KIT CONTENTS:

HOW TO INSTALL

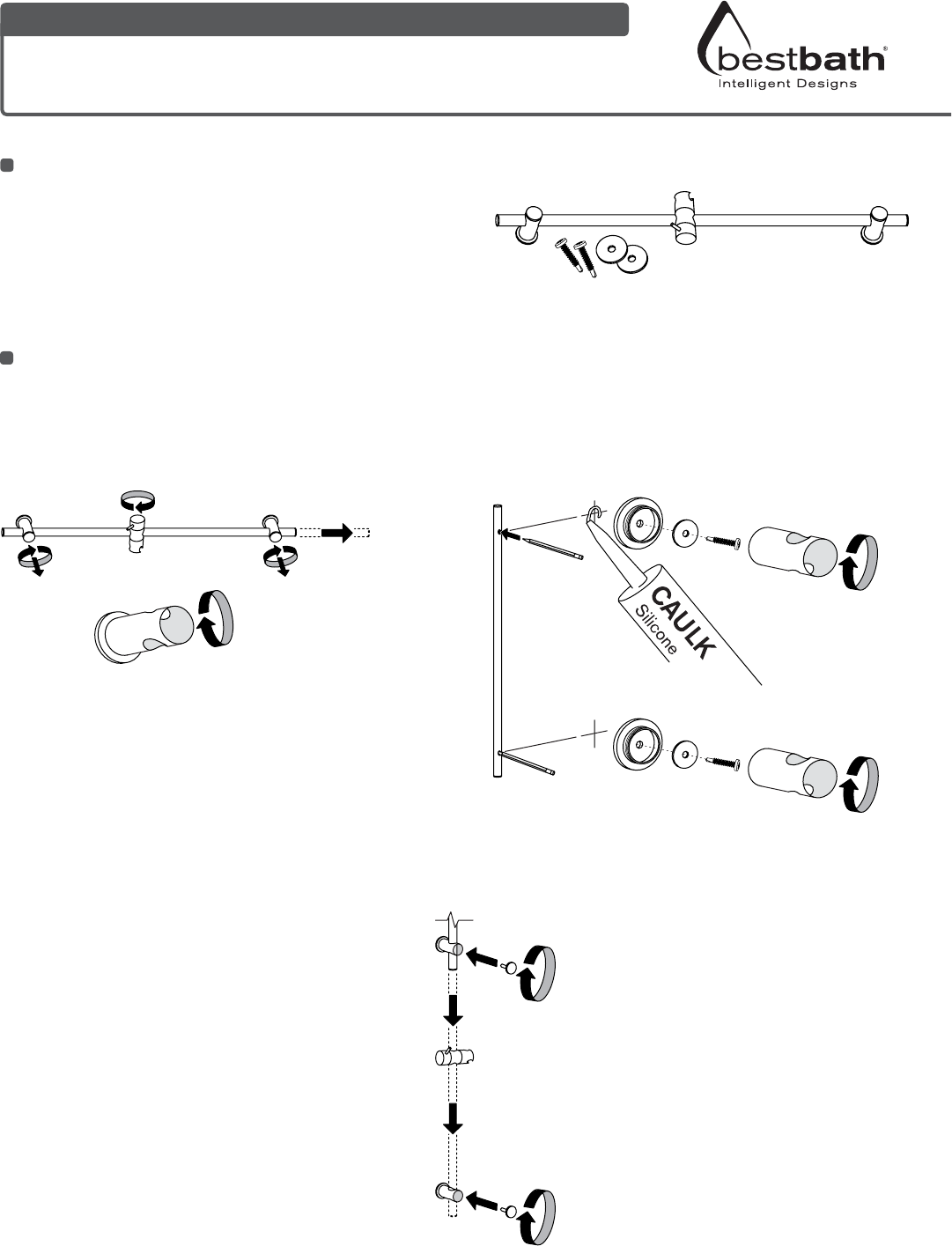

1081

•

Refer to Figures 1 – 3 below.

•

Glide bar assembly

•

#10 x 1" TEK screws (2)

•

#10 x

3

⁄4" Fender washers (2)

Standard 26" Glide Bar

DISASSEMBLE KIT PARTS

Figure 1

MARK AND INSTALL FLANGES

Figure 2

RE-ASSEMBLE GLIDE BAR ON FLANGES

Figure 3

KIT CONTENTS (ASSEMBLED)

Page 10

INSTALLATION INSTRUCTIONS

HOW TO INSTALL

ACCESSORY KIT CONTENTS:

MATERIALS & SUPPLIES NEEDED:

APPLICATION:

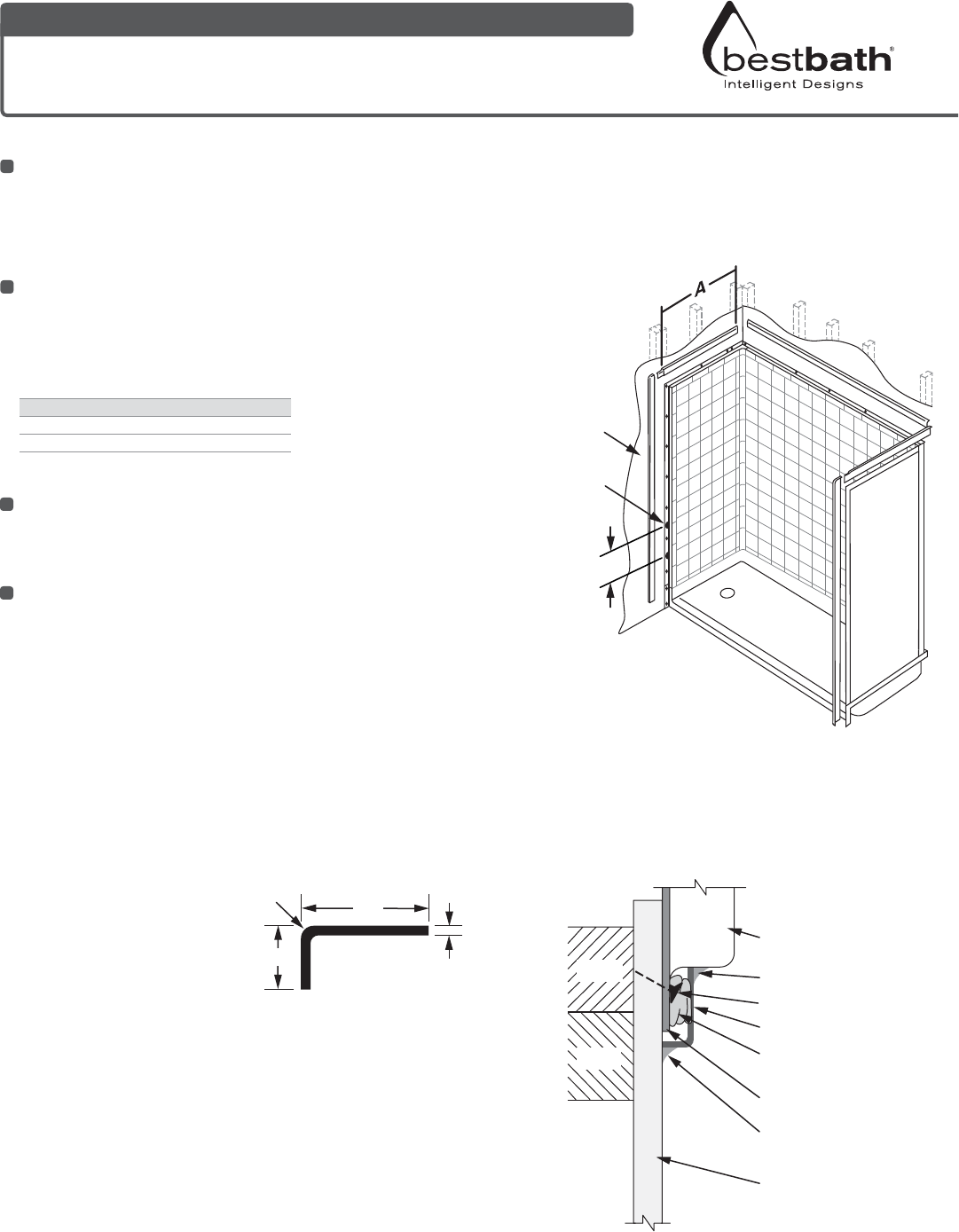

Flange Trim Kit for Wing Wall

•

Back wall section

•

Typical side front sections (2)

•

Typical side top section

•

Universal side top section

•

Wing wall top section

•

Loctite

®

Power Grab

®

construction adhesive

•

100% silicone

•

Paintable latex caulk

Installation:

1. Measure the distance along the back wall between the drywall

on each side of the shower.

2. Trim the back wall section to the correct size with a hacksaw.

3. Apply dollops of Power Grab

®

adhesive, approximately

3

⁄4" tall

and spaced 8" apart, to the nailing flange. Press the trim in

place.

4. Repeat Steps 1– 3 with the remaining sections.

5. Caulk around all edges. Use 100% silicone between shower

and trim; use paintable latex between trim and drywall

(Figure3).

For use as an easy way of covering the nailing flange where drywall

or other wall material is already installed BEHIND a shower with a

wing wall.

1083

Loctite and Power Grab are registered trademarks of Henkel Corp.

Power Grab

®

adhesive

8"

Figure 1

TRIM CROSS-SECTION

1

⁄8" radius

1

1

⁄4"

3

⁄32"

5

⁄8"

Figure 2

LEFT WING WALL SHOWN

Figure 4

TRIM CROSS-SECTION (INSTALLED)

Shower

Screw head

Silicone

Flange trim

Power Grab

®

construction adhesive

Shower nailing flange

Latex caulk (paintable)

Drywall

Figure 3

Stud

Stud

TRIM SHOWN BEFORE INSTALLATION

Make sure you measure horizontal side pieces from the "step" and

not from the end. See dimension A below.

Page 11

INSTALLATION INSTRUCTIONS

HOW TO INSTALL

ACCESSORY KIT CONTENTS:

MATERIALS & SUPPLIES NEEDED:

1084

Flange Trim Kit for Remodel

Part Numbers FTKR3, XFTKR3, and FTKTR3

•

Back wall section

•

Left front section

•

Left top section

•

Right front section

•

Right top section

•

Loctite

®

Power Grab

®

construction adhesive (2)

•

100% silicone

•

Paintable latex caulk

1. Measure the distance along the back wall between the drywall

on each side of the shower.

2. Trim the back wall section to the correct size with a hacksaw.

3. Apply dollops of Power Grab

®

adhesive, approximately

3

⁄4" tall

and spaced 8" apart, on both the nailing flange and drywall.

Press the trim in place.

4. Repeat Steps 1– 3 with the remaining sections.

5. Clear away any excess adhesive, then caulk around all edges.

Use 100% silicone between shower and trim; use paintable

latex between trim and drywall (Figures 3 and 4).

For use on remodels where dry wall is either:

– cut out to install the shower (Figure 3); or

– damaged in such a way that it will not be concealed by our

narrower 1

1

⁄4" FTK125 molding kit (Figure 4).

Kit Part Number Shower Height

FTKR3 42" to 83"

XFTKR3 83" to 94

1

⁄2"

FTKTR3 15" to 42"

Power Grab

®

adhesive

8"

Drywall

TRIM CROSS-SECTION

1

⁄8" radius

3"

3

⁄32"

3

⁄8"

Figure 2

TYPICAL TRIM CROSS-SECTION

(INSTALLED)

Stud

Stud

Shower

Screw head

Screw head

Silicone

Flange trim

Power Grab

®

construction adhesive

Power Grab

®

construction adhesive

Shower nailing flange

Latex caulk (paintable)

Drywall

Figure 3

NON-TYPICAL TRIM CROSS-SECTION,

INSTALLED ON SHOWER OVER DAMAGED DRYWALL

Shower

Screw head

Screw head

Silicone

Flange trim

Power Grab

®

construction adhesive

Power Grab

®

construction adhesive

Shower nailing flange

Latex caulk (paintable)

Drywall

Stud

Stud

Figure 4

Damaged drywall

Use when drywall is damaged beyond coverage with the 1

1

⁄

4

" kit.

Figure 1

Loctite and Power Grab are registered trademarks of Henkel Corp.

APPLICATION:

TRIM SHOWN BEFORE INSTALLATION

Make sure you measure horizontal side pieces from the "step" and

not from the end. See dimension A below.

Page 12

INSTALLATION INSTRUCTIONS

APPLICATION:

HOW TO INSTALL

1085

Flange Trim Kit with Reveal

Part Numbers FTK125RVL and FTK125DRVL

MATERIALS & SUPPLIES NEEDED:

•

Paintable latex caulk

Power Grab

®

adhesive

8"

Installation:

1. Measure the distance along the back wall between the drywall

on each side of the shower.

2. Trim the back wall section to size with a hacksaw.

3. Apply dollops of Power Grab

®

adhesive, approximately

3

⁄4" tall

and spaced 8" apart, to the nailing flange. Press the trim in

place.

4. Repeat Steps 1– 3 with the remaining sections.

5. Clear away any excess adhesive, then caulk around all edges.

Use 100% silicone between shower and trim; use paintable

latex between trim and drywall (Figure3).

For use as an easy way of covering the nailing flange on showers

or tub/showers with one or two reveal-type flanges where drywall

or other wall material is already installed BEHIND the unit.

Figure 1

TRIM CROSS-SECTION

1

⁄8" radius

1

1

⁄4"

3

⁄32"

5

⁄8"

Figure 2

RIGHT REVEAL SHOWN

Figure 4

Drywall

ACCESSORY KIT CONTENTS:

•

Non-reveal front section (2)

•

Non-reveal top section

•

Reveal front section (1 or 2*)

•

Reveal top section (1 or 2*)

•

Back wall section

•

Loctite

®

Power Grab

®

construction adhesive

•

100% silicone

* Doubles will have 2 sections.

Kit Part Number Type Shower Height

FTK125RVL Single reveal 42" to 82

3

⁄4"

XFTK125RVL Single reveal 83" to 94

1

⁄2"

FTK125DRVL Double reveal 42" to 82

3

⁄4"

XFTK125DRVL Double reveal 83" to 94

1

⁄2"

TRIM CROSS-SECTION (INSTALLED)

Figure 3

Shower

Stud

Screw head

Silicone

Flange trim

Power Grab

®

construction adhesive

Shower nailing flange

Latex caulk (paintable)

Drywall

Stud

Loctite and Power Grab are registered trademarks of Henkel Corp.

TRIM SHOWN BEFORE INSTALLATION

Make sure you measure horizontal side pieces from the "step" and

not from the end. See dimension A below.

Page 13

INSTALLATION INSTRUCTIONS

1086

•

Back wall section

•

Left front section

•

Left top section

•

Right front section

•

Right top section

•

Loctite

®

Power Grab

®

construction adhesive

•

100% silicone

•

Paintable latex caulk

1. Measure the distance along the back wall between the drywall

on each side of the shower.

2. Trim the back wall section to the correct size with a hacksaw.

3. Apply dollops of Power Grab

®

adhesive, approximately

3

⁄4" tall

and spaced 8" apart, to the nailing flange. Press the trim in

place.

4. Repeat Steps 1– 3 with the remaining sections.

5. Clear away any excess adhesive, then caulk around all edges.

Use 100% silicone between shower and trim; use paintable

latex between trim and drywall (Figure3).

Kit Part Number Shower Height

FTK125 83" or less

XFTK125 83" to 94

1

⁄2"

Power Grab

®

adhesive

8"

Drywall

Figure 1

Flange Trim Kit for New Construction

Part Numbers FTK125 and XFTKT125

For use as an easy way of covering the nailing flange where drywall

or other wall material is already installed BEHIND a shower or

tub-shower unit.

TRIM CROSS-SECTION

1

⁄8" radius

1

1

⁄4"

3

⁄32"

1

⁄2"

Figure 2

TRIM CROSS-SECTION (INSTALLED)

Shower

Stud

Stud

Screw head

Silicone

Flange trim

Power Grab

®

construction adhesive

Shower nailing flange

Latex caulk (paintable)

Drywall

Figure 3

Loctite and Power Grab are registered trademarks of Henkel Corp.

APPLICATION:

HOW TO INSTALL

MATERIALS & SUPPLIES NEEDED:

ACCESSORY KIT CONTENTS:

TRIM SHOWN BEFORE INSTALLATION

Make sure you measure horizontal side pieces from the "step" and

not from the end. See dimension A below.

Page 14

INSTALLATION INSTRUCTIONS

ACCESSORY KIT CONTENTS:

1088

Window Trim Kit — up to 37" width

Part Numbers WTK37 and WTK37H (with header)

HOW TO INSTALL

1. Cut side pieces (B) to length and width (Figure 3). For

cut edges that will not be covered with silicone, use a jig

saw with a bi-metal blade to help prevent a rough edge;

otherwise use a power saw.

2. Install side pieces with Power Grab

®

adhesive and brace or

tape as needed until the adhesive hardens.

3. Cut sill piece (A) to length and width (cut slightly narrower

than side pieces) and install tipped forward approximately

2° (or

1

⁄16" –

1

⁄8") for water run-off (Figure 4).

4. Cut top trim pieces (C) to fit and install (Figure 5).

5. Caulk all joints and corners with silicone (Figure 5).

•

A 36" long sill with 92° angle for drain-off; radii at left end

•

B 36" long side with 90° angle (2)

•

C Top trim (2) not included with header kit

•

D Loctite

®

Power Grab

®

construction adhesive

•

E 100% silicone

Optional header components:

•

F 36" long sill with 90° angle

•

G #8 x 1

1

⁄2" header mounting screws (4)

C

D

Power Grab

E

F

90° sill piece for header

B

34"

A

Radii

92°

36"

G

x4

37" max.

B

Sides cut to fit

Loctite Power Grab is a registered trademark of Henkel Corp.

CROSS-SECTION: SILL PIECE (A)

2"

8"

1

⁄2"

92°

Figure 1

CROSS-SECTION: SIDE PIECE (B)

(and optional header)

2"

8"

5

⁄8"

90°

Figure 2

Figure 5

Caulk with

silicone

Caulk

C

Top trim,

cut to fit

G

Pre-drill

holes

F

Optional

header

1

⁄

8

" -

1

⁄

4

"

Cut sill piece

1

⁄8"–

1

⁄4" narrower

than sides for

cleaner caulking

at corners.

88

°

A

Sill cut to fit

Figure 4

Figure 3

OPTIONAL HEADER

Page 15

INSTALLATION INSTRUCTIONS

ACCESSORY KIT CONTENTS:

HOW TO INSTALL

1. Cut side pieces (B) to length and width (Figure 3). For cut

edges that will not be covered with silicone, use a jig saw

with a bi-metal blade to help prevent a rough edge; otherwise

use a power saw.

2. Install side pieces with Power Grab

®

adhesive and brace or

tape as needed until the adhesive hardens.

3. Cut sill pieces (A1, A2) to length and width (cut slightly

narrower than side pieces) and install tipped forward

approximately 2° (or

1

⁄16" –

1

⁄8") for water run-off (Figure 4).

4. Cut top trim pieces (C) to fit and install (Figure 5).

5. Caulk all joints and corners with silicone (Figure 5).

•

A1 36" long sill with 92° angle for drain-off; radii on left end

•

A2 36" long sill with 92° angle for drain-off; radii on right end

•

B 36" long side with 90° angle (2)

•

C Top trim (2) not included with header kit

•

D Loctite

®

Power Grab

®

construction adhesive

•

E 100% silicone

Optional header components:

•

F1 36" long sill with 90° angle; radii on left end

•

F2 36" long sill with 90° angle; radii on right end

•

G #8 x 1

1

⁄2" header mounting screws (4)

•

H #8 x

1

⁄2" screws (4) with header connecting strip

1087

Window Trim Kit — up to 73" width

Part Numbers WTK73 and WTK73H (with header)

C

D

Power Grab

E

A2

Radii

F1, F2

90° sill pieces for header

Radii

Radii

B

34"

A1

Radii

92°

36"

G

x4

H

x4

Loctite Power Grab is a registered trademark of Henkel Corp.

CROSS-SECTION: SILL PIECE (A)

2"

8"

1

⁄2"

92°

Figure 1

90°

CROSS-SECTION: SIDE PIECE (B)

(and optional header)

2"

8"

5

⁄8"

Figure 2

73" max.

B

Sides cut to fit

Figure 3

Butt radiussed

ends together

G

Pre-drill

holes

H

Connecting Strip

(Pre-drill all holes;

countersink when

necessary)

F

Optional

header

A

Sill cut to fit

1

⁄

8

" -

1

⁄

4

"

Cut sill piece

1

⁄8"–

1

⁄4" narrower

than sides for

cleaner caulking

at corners.

88

°

Figure 4

Optional Header:

OPTIONAL HEADER

Figure 5

C

Top trim

cut to fit

Caulk

Caulk with

silicone

Reorder #FORM1034 6/18

Goof Off is a registered trademark of W.M. Barr Company Inc.

Bestbath and WaterStopper are registered trademarks of Best Bath Systems Inc. © 2018 Best Bath Systems Inc. All rights reserved.

BESTBATH SHOWER AND TUB

1089

Basic Cleaning

Best cleaning results are obtained by using automotive paste wax or gel gloss on the walls

only. The walls of the shower bathing unit should be waxed before use and then once every

two or three months. A furniture wax may also be used.

In almost all instances, polish or paste wax will remove dirt accumulated during normal use.

If a cleaner is needed, use only a non-abrasive liquid. Cleaners designed specifically for

fiberglass work very well.

!

Do not apply wax to the floor of the shower, shower pan or tub! This could

make the surface slippery and increase the risk of injury due to falling.

Stain and Residue Removal

•

Stains or burns can be removed by using an automotive rubbing compound, which will

also restore surface luster.

•

Difficult stains may require light sanding with wet 600 grit or finer sandpaper prior to using

rubbing compound.

•

The label on the inside of the unit may only be removed by the occupant. The adhesive

residue from this label can be removed with lighter fluid, nail polish remover or Goof Off

®

Remover (available at most hardware stores).

!

Avoid using caustic drain openers/clog removers (such as Drano) as they

can damage the surface if allowed to stand.

Cleaning and Maintenance

Recommendations

It is important to perform regular cleaning and maintenance on your Bestbath

®

unit. Doing so will help ensure that continues to function at its best for many

years. Read and follow the care and maintenance recommendations noted

here and keep these care instructions for future reference.

•

DO NOT apply wax to the

floor of the shower, shower

pan or tub, as it could make

the surface slippery.

•

DO NOT use caustic drain

clog removers as they can

damage the surface if

allowed to stand.

CARING FOR YOUR BESTBATH SHOWER OR TUB