Gaugeable Tube Fittings and Adapter Fittings 1

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBE

FITTINGS

Gaugeable Tube Fittings

and Adapter Fittings

■

Available in tube sizes from 1/16 to 2 in. and 2 to 50 mm

■

Consistent gaugeability upon initial installation

■

Easy to disconnect and retighten

■

Wide variety of materials and configurations

■

Demonstrated reliability and performance

www.swagelok.com

2 Tube Fittings

TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

Features

■

Live-loaded, two-ferrule design.

■

Easy to install.

■

No torque is transmitted to tubing during installation.

■

Swagelok

®

gap inspection gauge ensures sufcient pull-up upon initial installation.

Two-Ferrule, Mechanical Grip Design

The two ferrules separate sealing and tube gripping

functions; each ferrule is optimized for its function.

The front ferrule creates a seal:

■

against the tting body

■

on the tubing outside diameter.

As the nut is turned, the back ferrule:

■

axially advances the front ferrule

■

radially applies an effective tube grip.

Advanced-Geometry, Hinging-Colleting

Back Ferrule Design

This design is standard on all 1/4 to 1 in. and 6 to

25 mm Swagelok stainless steel tube ttings to help

installers make more consistent, leak-tight tube

connections.

In these sizes, a patented case hardening process

and patented recessed and contoured geometry

provide a unique engineered advantage to the

Swagelok back ferrule, providing:

■

excellent gas-tight sealing and tube-gripping action

■

easily achieved proper installation

■

consistent remakes

■

excellent vibration fatigue resistance and tube

support

■

full compatibility with original Swagelok stainless

steel tube ttings of identical sizes.

Refer to 316 Stainless Steel Swagelok Tube Fittings

with Advanced Geometry Back Ferrules technical

report, MS-06-16, for additional information.

Front ferrule

Back ferrule

Tubing

Nut

Fitting body

During assembly of the advanced-geometry design

(above), the front ferrule is driven into the fitting body and

the tubing to create primary seals, while the back ferrule

hinges inward to create a strong grip on the tubing. The

back ferrule geometry allows for an improved engineering

hinging-colleting™ action that translates axial motion into

radial swaging action on the tube, yet operates with a low

assembly torque requirement.

Hinge point

Gaugeable Tube Fittings and Adapter Fittings 3

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBE

FITTINGS

Straight Fittings

Unions

Union, 14

Reducing Union,

15

Bulkhead Union

and Bulkhead

Reducing

Union, 16

Male Connectors

NPT, 17

ISO/BSP Tapered

Thread (RT), 18

ISO/BSP Parallel

Thread (RS), 19

ISO/BSP Parallel

Thread (RP), 20

Bulkhead

NPT, 21

SAE/MS

Straight Thread

(ST) and Long

SAE/MS Straight

Thread (ST), 21

O-Seal (SAE/MS

Straight Thread

and NPT), 22

AN and

AN Bulkhead

Fitting, 23

10-32 Thread,

M5×0.8 Thread,

and Metric

Thread (RS), 24

Features, 2

The Swagelok Tube

Fitting Advantage, 6

Compliance with Industry

Standards, 7

Materials, 8

O-Rings, 8

Cleaning and

Packaging, 8

Metric Swagelok Tube

Fittings, 9

Pressure Rating Basis and

Thread Specications, 9

Pressure Ratings, 10

Ordering Numbers and

Dimensions, 14

Weld Connectors

Tube Socket, 24

Male Pipe, 25

Female Connectors

NPT, 26

ISO/BSP Tapered

Thread (RT),

ISO/BSP Parallel

Thread (RJ and

RP), 27

ISO/BSP Parallel

Thread (RG,

Gauge), 28

Bulkhead

NPT, 28

Reducers

Reducer, 29

Long Reducer,

30

Bulkhead

Reducer, 30

Port Connectors

Port Connector

and Reducing

Port Connector,

31

Contents

Additional Products

■

For Alloy 2507 super duplex

tube ttings, refer to Gaugeable

Alloy 2507 Super Duplex Tube

Fittings catalog, MS-01-174.

■

For alloy 400 tube ttings,

refer to Gaugeable Alloy 400

Mechanically Attached Pipe

and Tube Fittings catalog,

MS-02-332.

■

For PFA tube ttings, refer to

PFA Tube Fittings catalog,

MS-01-05.

■

For medium- and high-pressure

tube ttings, refer to Medium-

and High-Pressure Fittings,

Tubing, Valves, and Accessories

catalog, MS-02-472.

4 Tube Fittings

TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

45° Elbows

Male

NPT, 39

Positionable,

SAE/MS Straight

Thread (ST), 39

Tees

Unions

Union and Reducing

Union, 40

Male

Branch, NPT (TTM) and

Adapter Tees, 42

Run, NPT (TMT), 43

Positionable Branch,

SAE/MS Straight

Thread (TTS) and

Positionable Branch,

ISO/BSP Parallel

Thread (TTR), 44

Positionable Run,

SAE/MS Straight

Thread (TST), 44

Positionable Run,

ISO/BSP Parallel

Thread (TRT), 45

Female

Run, NPT (TFT), 45

Branch, NPT (TTF),

46

Caps and Plugs

Cap, 32

Plug, 32

Vent Protectors

Mud Dauber, 32

90° Elbows

Unions

Union, 33

Male

NPT, 34

ISO/BSP Tapered

Thread (RT), 35

Reducing Elbow,

36

Positionable, ISO/BSP

Parallel Thread (PR)

and Positionable,

SAE/MS Straight

Thread (ST), 37

Weld

Tube Socket, 38

Male Pipe, 38

Female

NPT, 38

Cross

Union, 46

Application-Specic Fittings

Kwik-Clamp Flange

to Swagelok Tube

Fitting, 47

Orice Plate Fitting,

48

Bored-Through Fittings

For thermocouples, dip tubes, and heat

exchanger tees, 20

Tube Adapters

Tube Adapter Information, 49

Male

NPT and ISO/BSP

Tapered Thread (RT),

50

ISO/BSP Parallel

Thread (RS and RP),

51

SAE/MS Straight

Thread (ST) and O-Seal

(SAE/MS Straight

Thread), 52

AN Thread, 52

Pipe Weld, 53

Contents

Gaugeable Tube Fittings and Adapter Fittings 5

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBE

FITTINGS

Installation Instructions, 69

Swagelok Tube Fittings, 70

O-Seal Male Connectors, 70

Caps and Plugs, 71

Port Connectors, 71

Positionable Elbows and Tees, 72

Tube Adapters, 72

AN Thread Swivel Nut, 72

Weld Fittings, 73

Depth Marking Tool, 73

Non-Gaugeable Preswaging Tool, 73

Tools Required for Gaugable Preswaging

Tool Instructions, 74

Gaugeable Preswaging Tool

Instructions, 74

Gaugeable Preswaging Tool, Tube Fitting

Installation, 75

Gaugeability, 75

Chromatograph Fittings

Refer to Gaugeable

Chromatograph and

Column End Fittings

catalog, MS-02-173.

Dielectric Fittings

Refer to Dielectric

Fittings catalog,

MS-02-36-SCS.

Flanges

For ANSI, DIN, and JIS

anges, refer to Flange

Adapters catalog,

MS-02-200.

VCO

®

and VCR

®

Face Seal Fittings

Refer to VCR Metal

Gasket Face Seal

Fittings catalog,

MS-01-24 and VCO

O-Rings Face Seal

Fittings catalog

MS-01-28.

Contents

Female

NPT and ISO/BSP

Tapered Thread

(RT), 53

ISO/BSP Parallel

Thread (RP and RJ),

and ISO/BSP

Parallel Thread (RG,

Gauge), 54

AN Thread, 54

Additional Ordering

Information, 55

Replacement Parts

Nuts

Female, 57

Knurled Female, 57

Male, 57

Ferrules

Front, 58

Back, 58

Nut-Ferrule Set and

Package and

Ferrule Set and

Ferrule-Pak™

Package, 59

ISO/BSP Parallel Gaskets

Steel (RS Fitting),

Copper (RP Fitting),

Copper (RG, Gauge

Fitting), and PTFE

(RJFitting), 60

O-Rings

Buna N (O-Seal

Straight Threads

and O-Seal Pipe

Threads) and

Fluorocarbon FKM

(ISO/BSP Parallel

Threads and

SAE/MS Straight

Threads), 61

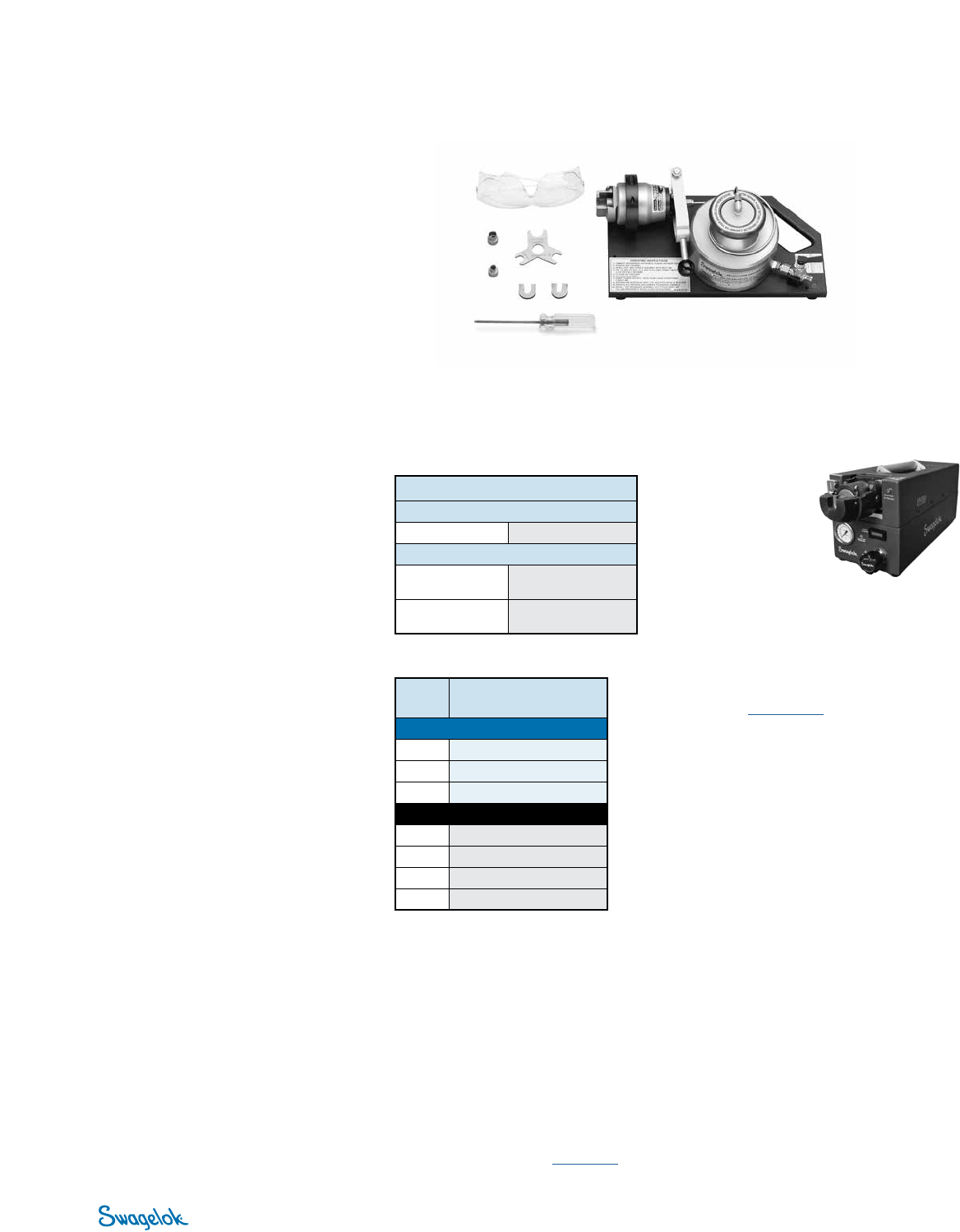

Tools and Accessories

Hydraulic Swaging Units, 62

Preswaging Tools, 65

Wrenches, 66

Gap Inspection

Gauges and Depth

Marking Tools, 67

Bulkhead Retainers,

68

Inserts for Soft

Plastic Tubing, 68

For liquid leak detectors, lubricants,

and sealants, refer to Leak Detectors,

Lubricants, and Sealants catalog,

MS-01-91.

For tube benders and tube preparation

tools, refer to Tubing Tools and

Accessories catalog, MS-01-179.

Gaugeability, 69

6 Tube Fittings

TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

Messages from customers credit

Swagelok components and tube

ttings, along with Swagelok distributor

support, as having played a major role

in helping them succeed.

Swagelok continues to improve the

performance and reliability of the tube

tting for use in thousands of diverse

applications—including research,

alternative fuels, analytical and process

instrumentation, oil and gas, power,

petrochemical, and semiconductor

industries—and addressing such

critical issues as:

■

gas-tight seal

■

vibration (tube grip)

■

thermal shock

■

compliance with industry standards

■

installation

■

corrosion

■

intermix/interchange.

Gas-tight Seal

Excellent sealing and consistent

reassembly help ensure accurate

measurements of process

parameters—air, steam, fuel, and

water—to keep your plant operating

efciently. Moreover, Swagelok tube

ttings minimize fugitive emissions,

as well as process uid leakage and

operation costs.

Contact your authorized Swagelok sales

and service representative for more

information about Swagelok Energy

Emissions Surveys or to schedule a

survey.

Vibration (Tube Grip)

The patented case-hardening process

and back-ferrule geometry provide

excellent vibration fatigue resistance

and tube support—even in harsh

or stressful environments, such as

hydrocarbon processing, on-vehicle

applications, or rotary equipment

applications.

Swagelok has conducted vibration

tests, which show that the Swagelok

tube tting with advanced geometry

hinging-colleting back ferrule isolates

and protects the stress riser that is

generated along the tube during the

gripping part of assembly. The colleting

portion of the back ferrule allows

more material to contact the tube, for

additional support. This colleting action

enhances gripping performance and

provides both direct and axial support

to the gripping function. This design

minimizes the effects of bending

deection at the point of grip on the

tubing.

Contact your authorized Swagelok

representative for more information

about vibration test reports.

The Swagelok Tube Fitting Advantage

“Over 10 000 fittings

and not a single leak.”

“Used exclusively on our

equipment and has proven

to be very reliable and easy

to maintain.”

“

I have used Swagelok

fittings from when I was

a technician through

today in my role in facility

management. Would

recommend them for any

use.”

Gaugeable Tube Fittings and Adapter Fittings 7

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBE

FITTINGS

metallurgical, and mechanical

uniformity that allow predictable,

repeatable installation.

Swagelok authorized sales and service

centers offer installation training

seminars that provide additional

information on:

■

The requirements for making safe,

leak-tight connections

■

A variety of tools and accessories

designed for use with Swagelok tube

ttings.

Corrosion

Swagelok tube ttings are available

in a variety of materials, including

optimized 316 stainless steel chemistry

with elevated nickel, chromium, and

other elements for superior corrosion

resistance in a variety of applications,

including chemical processing, sour

gas and subsea systems.

Swagelok has conducted tests in

accordance with ASTM B117-95 to

evaluate the corrosion resistance of

Swagelok tube ttings.

Contact your authorized Swagelok

representative for more information

about corrosion resistance test reports.

Intermix/Interchange

Swagelok recommends NO intermix/

interchange of Swagelok tube tting

components with other manufacturers’

components.

■

No industrial design standard

exists for two ferrule tube ttings.

Each company makes components

to its own design and not to any

recognized standards.

■

Interchanging and intermixing

tube tting components can result

in unpredictable performance,

environmental releases, increased

costs, and can be dangerous in

critical applications.

Thermal Shock

The elastic, live-loaded two-ferrule

design compensates for changes in

temperature during system start-up

and shutdown and helps eliminate

leakage related to rapid thermal

expansion or contraction.

Swagelok has conducted tests

that demonstrated the capability of

Swagelok tube ttings to withstand

thermal shock and high temperature.

Contact your authorized Swagelok

representative for more information

about thermal shock test reports.

Compliance with

Industry Standards

Swagelok Company works with

standards organizations around the

world to provide you with products that

address your needs.

Stainless steel Swagelok tube ttings

used with 316 stainless steel and 316 Ti

stainless steel alloy tubing as shown

in the table have been tested to the

requirements of ECE R110. In addition,

stainless steel Swagelok tube ttings

are available with EC-79 certication.

NACE - Sour Gas

Swagelok offers ttings in materials that

meet the metallurgical requirements of

NACE MR0175/ISO 15156 and MR0103.

Refer to NACE MR0175/ISO 15156

Compliant Swagelok Fittings,

MS-06-124, for additional information.

NORSOK

Fittings manufactured from alloy 2507

and 6MO are NORSOK M-630 and

M-650 compliant as standard. Contact

your authorized sales and service

representative for additional details.

Third-Party Agencies

■

Vd TÜV

■

TÜV SUD Automotive

■

DVGW

■

Department of the Navy (U.S.)

■

Det Norske Veritas (DNV)

■

Nippon Kaiji Kyokai (NK)

■

American Bureau of Shipping (ABS)

■

Lloyd’s Register of Shipping (LR)

■

Bureau Veritas (BV)

■

RS Maritime

■

Canadian Provincial Agencies (CRN)

■

Russian GOST TR (Customs Union

Countries)

■

UkSepro for Ukraine

■

Inspecta Nuclear for Sweden

■

METI/KHK

■

Engineers India Limited (EIL)

For a complete listing, refer to the

Tube Fitting Performance Product Test

Reports PTRs and Third-Party Product

Approvals and Registrations,

MS-06-108.

See Materials, page 8; Thread

Specications, page 9; and

Pressure Ratings, page 9, for more

information about the specications

to which Swagelok tube ttings are

manufactured.

Contact your authorized Swagelok

representative for more information

about Swagelok tube tting

certications.

Installation

The Swagelok tube tting installation

advantages:

■

Easy to install

■

No torque is transmitted to tubing

during installation

■

Swagelok gap inspection gauge

assures sufcient pull-up upon initial

installation.

Swagelok tube tting components

provide exceptional dimensional,

Tube OD Wall Thickness

3 to 16 mm 0.7 to 2.5 mm

1/8 to 5/8 in. 0.028 to 0.095 in.

8 Tube Fittings

TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

O-Rings

O-seal ttings include a 70 durometer Buna N O-ring. Other

straight-thread ttings with O-rings include a 90 durometer

uorocarbon FKM O-ring. Other O-ring materials are available

upon request. O-rings are coated with a thin lm of silicone-

based lubricant. Removal of factory-applied lubricants may

alter performance.

For ST and ST positionable ttings used in ECE-R110

applications, add the DE O-ring sufx to the ordering number.

Example: SS-600-1-6STDE

Materials

Cleaning and Packaging

Fitting components are cleaned to remove machine oil, grease,

and loose particles. For more information, see Swagelok

Standard Cleaning and Packaging (SC-10) catalog, MS-06-62.

Fittings are available individually bagged; add CP to the

ordering number. Example: SS-200-6CP

On request, ttings can be specially cleaned and packaged.

Cleaning and packaging options can be found in Special

Cleaning of Swagelok Tube Fittings, SCS-00663. Contact

your authorized Swagelok representative for details.

Fittings cleaned and packaged in accordance with ASTM G93

Level C, will have the front ferrule silver-plated and Krytox®

240 AC applied to the internal surface of the nut. To order, add

BQ to the ordering number.

Example: SS-400-1-4BQ

Oxygen Service Hazards

For more information about hazards and risks of oxygen-

enriched systems, see the Swagelok Oxygen System Safety

technical report catalog, MS-06-13.

Materials Standards

➀ Straight ttings and tube adapters.

➁ Elbows, crosses, and tees.

➂ All straight fittings and tube adapters and 1/4 and 3/8 in.; 6 and 10 mm

elbows, crosses, and tees.

➃ Elbows, crosses, and tees larger than 3/8 in. and 10 mm.

➄ Refer to PFA Tube Fittings catalog, MS-01-05.

➅ Refer to Gaugeable Alloy 2507 Super Duplex Tube Fittings catalog,

MS-01-174.

➆ Contact your authorized Swagelok representative for materials not listed.

Material

➆

Bar Stock

➀

Forgings

➁

316 stainless

steel

ASTM A276, ASTM A479,

ASME SA479, EN 1.4401

ASTM A182,

ASME SA182, EN 1.4401

6-Moly ASTM A479 ASTM A182

Alloy 400 ASTM B164 ASTM B564, ASME SB564

Alloy 600 ASTM B166, ASME SB166 ASTM B564, ASME SB564

Alloy 625 ASTM B446

➂

ASTM B564, ASME SB564

➃

Alloy 825 ASTM B425 ASTM B564, ASME SB564

Alloy C-276 ASTM B574 ASTM B564

Aluminum ASTM B211 ASTM B247

Brass ASTM B16, ASTM B453 ASTM B283

Carbon steel ASTM A108 —

PFA

➄

— ASTM D3307 Type I

PTFE ASTM D1710 ASTM D3294

Alloy 2507

➅

ASTM A479 ASTM A182

Titanium

(grade 4)

ASTM B348 ASTM B381

Additional Processing

Fitting bodies are processed for improved performance, as

listed below. No additional processing is required for alloy 625,

alloy 825, brass, 316 stainless steel, and PTFE materials.

■

Over 1 in./25 mm ttings are supplied with a package of

uorinated-base with PTFE and tungsten disulde lubricant

for use in tting assembly.

■

Over 1 in./25 mm stainless steel ttings use stainless steel

ferrules with PFA coating. Applications above 450°F (232°C)

require silver-plated front ferrules and uncoated back

ferrules. To order ttings with silver-plated front ferrules

and uncoated back ferrules, add BM to the tting ordering

number.

Example: SS-2400-6BM

■

All carbon steel Swagelok tube ttings are supplied with

316 stainless steel back ferrules.

Fitting Body Material Process

Aluminum Anodized, hydrocarbon film

Alloy 400, alloy C-276,

alloy 600

Hydrocarbon film

Carbon steel (except weld bodies) Zinc plating

Carbon steel (weld bodies)

Hydrocarbon film chemical

conversion coating

Titanium Anodized

Gaugeable Tube Fittings and Adapter Fittings 9

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBE

FITTINGS

Pressure Rating Basis and Thread Specications

Thread Type (End Connection) Pressure Rating Basis Thread Type Reference Specification

Swagelok Tube Fittings

Swagelok tube fitting ends are rated to the working pressure

of tubing as listed in Swagelok Tubing Data, MS-01-107.

Careful selection of high-quality tubing is important when

installing safe, leak-tight systems.

Unified Inch Screw

Threads

ASME B1.1

NPT

ASME B31.3, Process Piping or pressure testing with a 4:1

design factor based on hydraulic fluid leakage.

NPT

ASME B1.20.1,

SAE AS71051

ISO/BSP (tapered)

(Swagelok RT fittings)

ASME B31.3, Process Piping or pressure testing with a 4:1

design factor based on hydraulic fluid leakage.

ISO/BSP (tapered)

Swagelok RT fittings

ISO 7, BS EN 10226-1,

JIS B0203

ISO/BSP (parallel)

(Swagelok RS fittings)

ISO 1179-3, ISO 228-1 Threads with Light-Duty Stud Ends

with Sealing by O-ring with Retaining Ring (types G and

H) or pressure testing with a 4:1 design factor based on

hydraulic fluid leakage.

ISO/BSP (parallel)

Swagelok RP and RS

fittings

ISO 228,

JIS B0202

ISO/BSP (parallel)

(Swagelok RP fittings)

ISO 1179-4, ISO 228-1 Threads with Stud Ends for general use

only with metal-to-metal sealing (type B) or pressure testing

with a 4:1 design factor based on hydraulic fluid leakage.

ISO/BSP (parallel)

Swagelok RP and RS

fittings

ISO 228,

JIS B0202

ISO/BSP (gauge)

(Based on EN 837-1 and 837-3)

(Swagelok RG and RJ fittings)

ASME B31.3, Process Piping or pressure testing with a 4:1

design factor based on hydraulic fluid leakage.

ISO/BSP (parallel)

Swagelok RG and RJ

fittings

ISO 228,

JIS B0202

SAE–Light Duty

(Swagelok ST fittings)

SAE J1926/3, Connections for General Use and Fluid

Power-Ports and Stud Ends with ASME B1.1 Threads and

O-ring Sealing-Part 3: Light-Duty (L-Series) Stud Ends or

pressure testing with a 4:1 design factor based on hydraulic

fluid leakage.

Unified Inch Screw

Threads

Swagelok ST fittings

ASME B1.1

SAE–Heavy Duty

(Swagelok STH fittings)

SAE J1926/2, Connections for General Use and Fluid

Power-Ports and Stud Ends with ASME B1.1 Threads and

O-ring Sealing-Part 2: Heavy-Duty (S-Series) or pressure

testing with a 4:1 design factor based on hydraulic fluid

leakage.

Unified Inch Screw

Threads Swagelok ST

fittings

ASME B1.1

Swagelok AN fittings

SAE J514, Hydraulic Tube Fittings or pressure testing with a

4:1 design factor based on hydraulic fluid leakage.

Unified Inch Screw

Threads

Swagelok AN fittings

ASME B1.1 UNJ,

SAE AS 8879

Pipe Thread Sealants

A thread sealant should always be used when assembling

tapered threads. SWAK™ anaerobic pipe thread sealant and

Swagelok PTFE tape are available. Refer to Leak Detectors,

Lubricants, and Sealants catalog, MS-01-91, for additional

information.

Metric Swagelok Tube Fittings

Metric tube ttings have a stepped shoulder on the body hex.

Shaped ttings, such as elbows, crosses, and tees, are

stamped MM for metric tubing and have no step on the forging.

Swagelok

metric

tube end

Swagelok

fractional

tube stub

No shoulder

Stepped identication

shoulders

Stepped identication

shoulders

Swagelok

metric tube

ends

Port Connectors, Reducers, and Tube

Adapters

Swagelok tube adapters with the machined groove are

rated to the highest suggested allowable working pressure,

see Swagelok Tubing Data, MS-01-107 for a tube outside

diameter and material in question.

10 Tube Fittings

TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

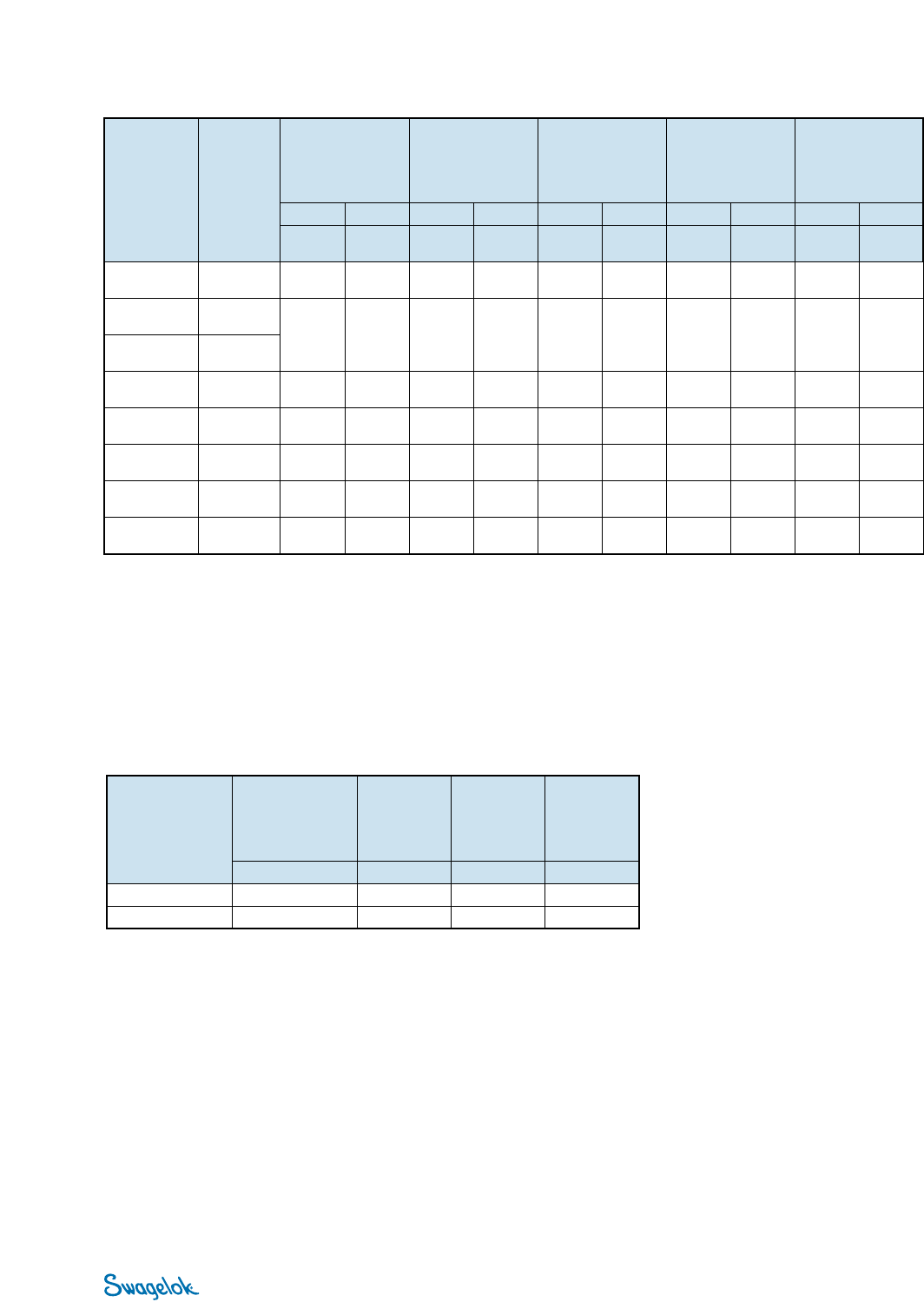

NPT/ISO Pipe Pressure Ratings

Ratings are based on ASME Code for Pressure Piping B31.3, Process Piping, at ambient temperature.

NPT/ISO

Pipe Size

in.

316 SS, Carbon

Steel, Alloy (600,

and C-276)

Brass and

Aluminum Alloy 400 Titanium

Alloy 2507 and

Alloy 625 6-Moly Alloy 825

Male Female Male Female Male Female Male Female Male Female Male Female Male Female

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

1/16

11 000

(757)

6 700

(461)

5 500

(378)

3 300

(227)

9 900

(682)

6 000

(413)

8 800

(606)

5 300

(365)

15 000

(1 033)

12 900

(888)

14 900

(1 026)

9 000

(620)

12 800

(881)

7800

(537)

1/8

10 000

(689)

6 500

(447)

5 000

(344)

3 200

(220)

9 000

(620)

5 800

(399)

8 000

(551)

5 200

(358)

15 000

(1 033)

12 500

(861)

13 500

(930)

8 800

(606)

11 600

(799)

7500

(516)

1/4

8 000

(551)

6 600

(454)

4 000

(275)

3 300

(227)

7 200

(496)

5 900

(406)

6 400

(440)

5 200

(358)

15 000

(1 033)

12 700

(875)

10 800

(744)

8 900

(613)

9 300

(640)

7600

(523)

3/8

7 800

(537)

5 300

(365)

3 900

(268)

2 600

(179)

7 000

(482)

4 700

(323)

6 200

(427)

4 200

(289)

15 000

(1 033)

10 200

(702)

10 500

(723)

7 100

(489)

9 000

(620)

6100

(420)

1/2

7 700

(530)

4 900

(337)

3 800

(261)

2 400

(165)

6 900

(475)

4 400

(303)

6 100

(420)

3 900

(268)

14 800

(1 019)

9 400

(647)

10 400

(716)

6 600

(454)

8 900

(613)

5700

(392)

3/4

7 300

(502)

4 600

(316)

3 600

(248)

2 300

(158)

6 500

(447)

4 100

(282)

5 800

(399)

3 600

(248)

10 000

(689)

8 900

(613)

9 800

(675)

6 200

(427)

8 500

(585)

5300

(365)

1

5 300

(365)

4 400

(303)

2 600

(179)

2 200

(151)

4 700

(323)

3 900

(268)

4 200

(289)

3 500

(241)

10 000

(689)

8 500

(585)

7 100

(489)

5 900

(406)

6 100

(420)

5100

(351)

1 1/4

6 000

(413)

5 000

(344)

3 000

(206)

2 500

(172)

5 400

(372)

4 500

(310)

4 800

(330)

4 000

(275)

10 000

(689)

9 600

(661)

8 100

(558)

6 700

(461)

6 900

(475)

5800

(399)

1 1/2

5 000

(344)

4 600

(316)

2 500

(172)

2 300

(158)

4 500

(310)

4 100

(282)

4 000

(275)

3 600

(248)

9 600

(661)

8 900

(613)

6 700

(461)

6 200

(427)

5 800

(399)

5300

(365)

2

3 900

(268)

3 900

(268)

1 900

(130)

1 900

(130)

3 500

(241)

3 500

(241)

3 100

(213)

3 100

(213)

7 500

(516)

7 500

(516)

5 200

(358)

5 200

(358)

4 500

(310)

4500

(310)

■

To determine pressure ratings in accordance with ASME B31.1, Power Piping:

■

carbon steel material—multiply by 0.85.

Stainless steel and brass material ratings remain the same.

■

To determine MPa, multiply bar by 0.10.

Pressure Ratings

Gaugeable Tube Fittings and Adapter Fittings 11

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBE

FITTINGS

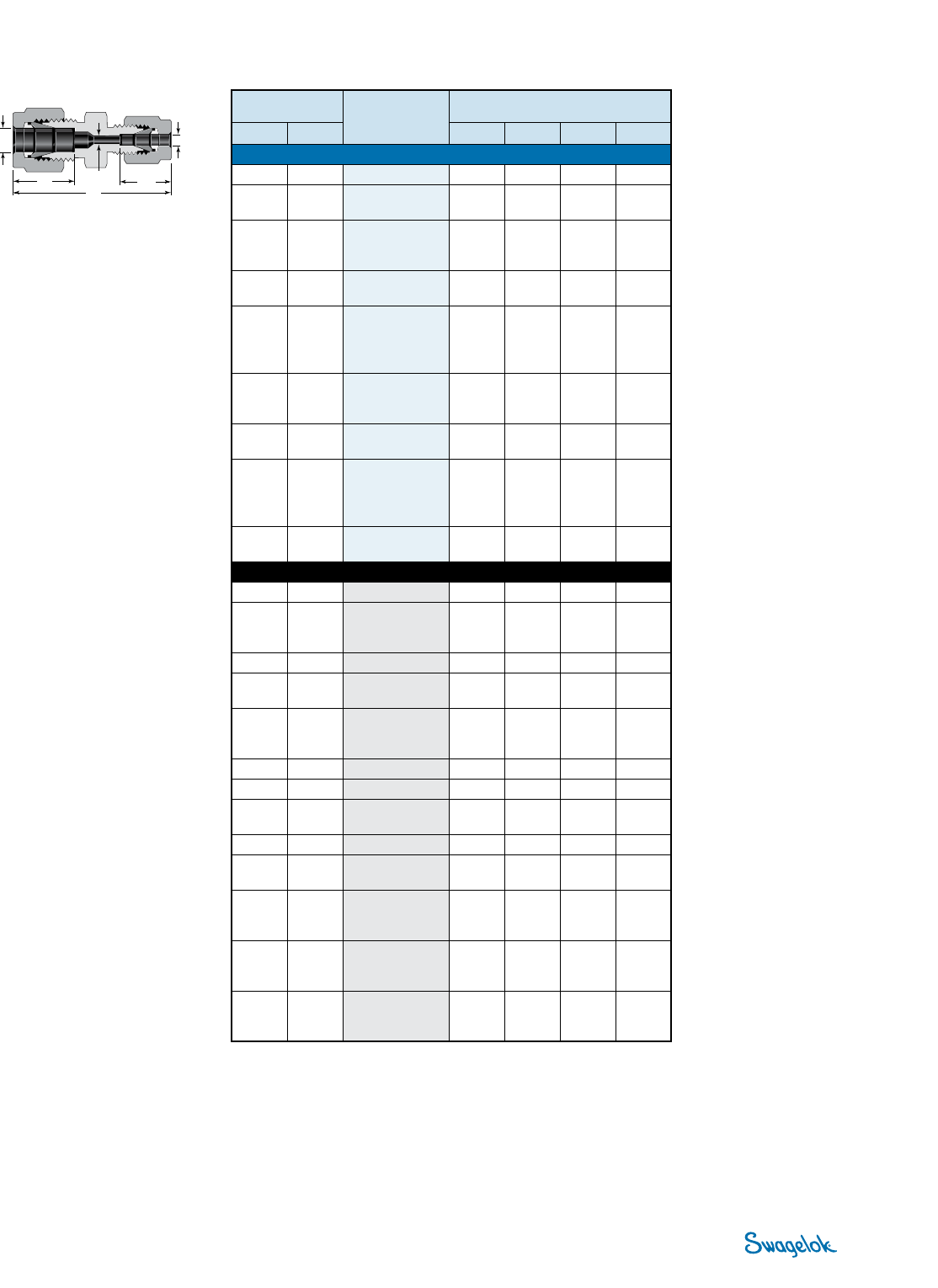

SAE/MS Fittings Pressure Ratings

Pressure ratings are based on SAE J1926/3 at ambient temperature.

SAE/MS

Thread

Size Designator

316 SS, Carbon Steel, and

Alloy (C-276, 2507, 625,

6-Moly, 825, and 600) Brass and Aluminum Alloy 400 Titanium

Non-

positionable Positionable

Non-

positionable Positionable

Non-

positionable Positionable

Non-

positionable Positionable

psig (bar) psig (bar) psig (bar) psig (bar) psig (bar) psig (bar) psig (bar) psig (bar)

5/16-24 2ST

5076 (350)

5076 (350)

2538 (175)

2538 (175)

4568 (315)

4568 (315)

4061 (280)

4061 (280)

3/8-24 3ST

7/16-20 4ST

4568 (315) 2277 (157) 4104 (283) 3654 (252)

1/2-20 5ST

9/16-18 6ST

4061 (280) 2030 (140) 3654 (252) 3248 (224)

3/4-16 8ST 4568 (315) 2175 (150) 4104 (283) 3654 (252)

7/8-14 10ST

3625 (250) 3045 (210) 1740 (120) 1522 (105) 3263 (225) 2741 (189) 2900 (200) 2436 (168)

1 1/16-12 12ST

1 3/16-12 14ST

3045 (210) 2538 (175) 1450 (100) 1261 (87) 2741 (189) 2277 (157) 2436 (168) 2030 (140)

1 5/16-12 16ST

1 5/8-12 20ST

2538 (175) 2030 (140) 1160 (80) 1015 (70) 2277 (157) 1827 (126) 2030 (140) 1624 (112)

1 7/8-12 24ST

2 1/2-12 32ST 2030 (140) 1522 (105) 1015 (70) 754 (52) 1827 (126) 1363 (94) 1624 (112) 1218 (84)

STH SAE/MS Heavy Duty Pressure Ratings

Pressure ratings are based on SAE J1926/2 at ambient temperature.

STH

SAE/MS

Thread

Size Designator

316 SS, Carbon Steel, and

Alloy (C-276, 2507, 625,

6-Moly, 825, and 600) Brass and Aluminum Alloy 400 Titanium

Non-

positionable Positionable

Non-

positionable Positionable

Non-

positionable Positionable

Non-

positionable Positionable

psig (bar) psig (bar) psig (bar) psig (bar) psig (bar) psig (bar) psig (bar) psig (bar)

3/8-24 3STH

9137 (630)

6091 (420)

4568 (315)

3045 (210)

8223 (567)

5482 (378)

7309 (504)

4873 (336)

7/16-20 4STH

1/2-20 5STH

9/16-18 6STH

3/4-16 8STH

7/8-14 10STH

1 1/16-12 12STH

6091 (420) 3045 (210) 5482 (378) 4873 (336)1 3/16-12 14STH

1 5/16-12 16STH 5076 (350) 2538 (175) 4568 (315) 4061 (280)

1 5/8-12 20STH

4061 (280)

4061 (280)

2030 (140)

2030 (140)

3654 (252)

3654 (252)

3248 (224)

3248 (224)

1 7/8-12 24STH 3045 (210) 1522 (105) 2741 (189) 2436 (168)

2 1/2-12 32STH 3045 (210) 2538 (175) 1522 (105) 1261 (87) 2741 (189) 2277 (157) 2436 (168) 2030 (140)

Pressure Ratings

12 Tube Fittings

TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

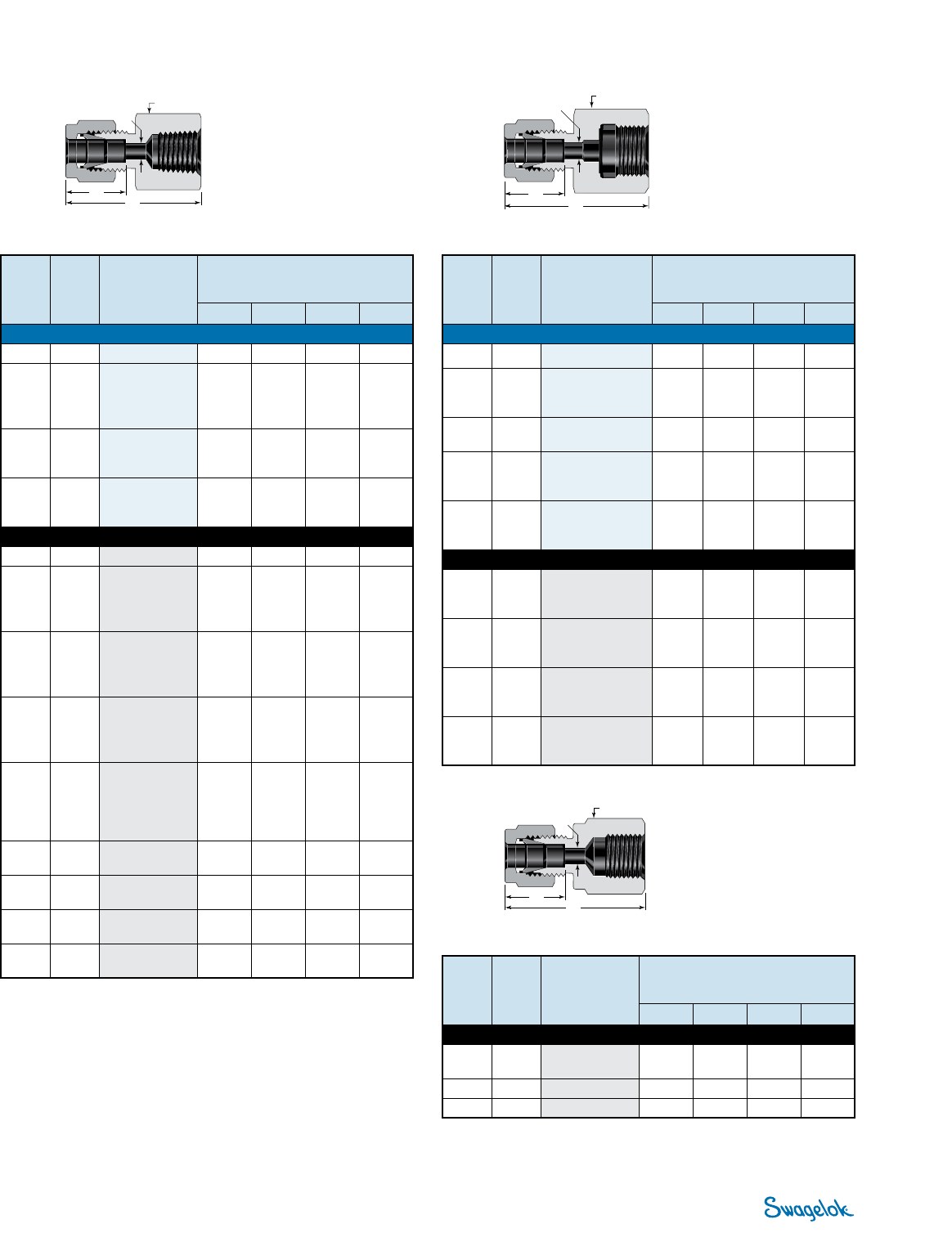

O-Seal Pressure Ratings

Stainless steel and carbon steel O-seal ttings up to 1 in. and

25 mm are rated to 3000 psig (206 bar).

Male AN (JIC) Fittings Pressure Ratings

Pressure ratings are at ambient temperature and apply to slide-on and crimped-on swivel nuts with a female gland.

Male AN

(JIC)

Thread Size Designator

316 SS and

Alloy (C-276,

2507, 625, 6-Moly,

825, and 600) Carbon Steel

Brass and

Aluminum Alloy 400 Titanium

Straight Shape Straight Shape Straight Shape Straight Shape Straight Shape

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

psig

(bar)

7/16-20 4AN

10 000

(689)

10 000

(689)

4 500

(310)

4 500

(310)

5 000

(345)

5 000

(345)

9 000

(620)

9 000

(620)

8 000

(551)

8 000

(551)

9/16-18 6AN

8 200

(564)

7 600

(523)

4 000

(275)

4 000

(275)

4 100

(282)

3 800

(262)

7 380

(508)

6 840

(471)

6 560

(452)

6 080

(410)

3/4-16 8AN

1 1/16-12 12AN

7 000

(482)

6 300

(434)

3 000

(210)

3 000

(210)

3 500

(241)

3 150

(217)

6 300

(434)

5 670

(391)

5 600

(386)

5 040

(347)

1 5/16-12 16AN

5 000

(344)

4 100

(282)

2 500

(170)

2 500

(170)

2 500

(172)

2 050

(141)

4 500

(310)

3 690

(254)

4 000

(276)

3 280

(226)

1 5/8-12 20AN

2 000

(140)

2 000

(140)

2 000

(140)

2 000

(140)

1 000

(69)

1 000

(69)

1 800

(124)

1 800

(124)

1 600

(110)

1 600

(110)

1 7/8-12 24AN

1 500

(105)

1 500

(105)

1 500

(105)

1 500

(105)

700

(48)

750

(52)

1 350

(93)

1 350

(93)

1 200

(83)

1 200

(83)

2 1/2-12 32AN

1 125

(80)

1 125

(80)

1 125

(80)

1 125

(80)

500

(34)

560

(39)

1 010

(70)

1 010

(70)

900

(62)

900

(62)

Positionable, ISO/BSP Parallel Thread (PR)

Pressure Ratings

Pressure ratings are at ambient temperature.

ISO/BSP Male

Pipe Size

in.

316 SS, Carbon

Steel, and Alloy

(C-276, 2507, 625,

6-Moly, 825, and

600

Brass and

Aluminum Alloy 400 Titanium

psig (bar) psig (bar) psig (bar) psig (bar)

1/8, 3/16, 1/4, 3/8 4568 (315) 2277 (157) 4104 (283) 3654 (252)

1/2, 3/4, 1 2320 (160) 1160 (80) 2088 (144) 1856 (128)

Pressure Ratings

Gaugeable Tube Fittings and Adapter Fittings 13

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBE

FITTINGS

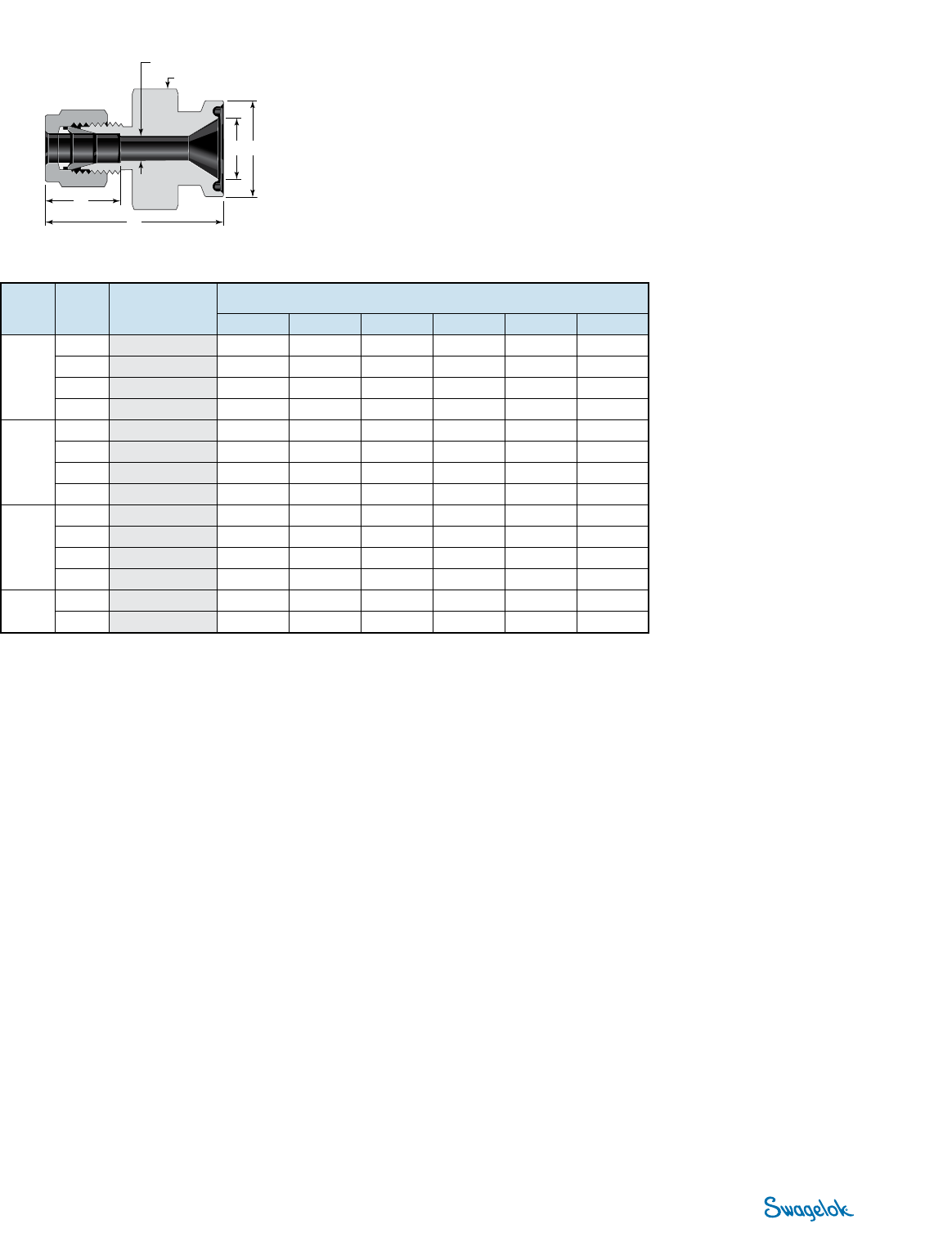

ISO 228/BSP Parallel Thread (RS and RP)

Pressure Ratings

Hydraulic pressure ratings are based on ISO 1179 at ambient

temperature.

■

RS and RP male connectors were tested with RP female

connectors.

■

RS end connections were tested with bonded RS gaskets.

■

RP connections were tested without a gasket.

■

Gasket selection is the responsibility of the system

designer and user and may affect product performance.

Pressure Ratings

ISO/BSP Male

Pipe Size

in.

316 SS, Carbon

Steel, and Alloy

(C-276, 2507, 625,

6-Moly, 825, and

600)

Brass and

Aluminum Alloy 400 Titanium

psig (bar) psig (bar) psig (bar) psig (bar)

1/8, 1/4, 3/8 5800 (400) 2900 (200) 5220 (360) 4640 (320)

1/2 4700 (324) 2350 (162) 4220 (291) 3750 (259)

3/4

3620 (250) 1810 (125) 3260 (225) 2900 (200)

1

1 1/4

2320 (160) 1160 (80) 2080 (144) 1850 (128)

1 1/2

ISO/BSP Male

Pipe Size

in.

316 SS, Carbon

Steel, and Alloy

(C-276, 2507, 625,

6-Moly, 825, and

600)

Brass and

Aluminum Alloy 400 Titanium

psig (bar) psig (bar) psig (bar) psig (bar)

1/8, 1/4, 3/8 5800 (400) 2900 (200) 5200 (360) 4640 (320)

1/2 4700 (324) 2350 (162) 4220 (291) 3750 (259)

3/4 2320 (160) 1160 (80) 2080 (144) 1850 (128)

1

1450 (100) 720 (50) 1300 (90) 1160 (80)1 1/4

1 1/2

ISO 228/BSP Parallel Thread RS Pressure Ratings

ISO 228/BSP Parallel Thread RP Pressure Ratings

ISO/BSP Male

Pipe Size

in.

316 SS, Carbon

Steel, and Alloy

(C-276, 2507, 625,

6-Moly, 825, and

600)

Brass and

Aluminum Alloy 400 Titanium

psig (bar) psig (bar) psig (bar) psig (bar)

1/8

5700 (392) 2850 (196) 5110 (352) 4560 (314)1/4

3/8

1/2 3900 (288) 1950 (134) 3490 (240) 3120 (215)

ISO 228/BSP/JIS Parallel Thread RG and RJ Pressure Ratings

14 Tube Fittings

TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

Tube

OD

Basic

Ordering

Number

Dimensions

A D E

Dimensions, in.

1/16 -100-6 0.99 0.34 0.05

1/8 -200-6 1.40 0.50 0.09

3/16 -300-6 1.47 0.54 0.12

1/4 -400-6 1.61 0.60 0.19

5/16 -500-6 1.69 0.64 0.25

3/8 -600-6 1.77 0.66 0.28

1/2 -810-6 2.02 0.90 0.41

1/2 -810-6-0030

➀

4.30 —

0.50

5/8 -1010-6 2.05

0.96

3/4 -1210-6 2.11 0.62

7/8 -1410-6 2.17 1.02 0.72

1 -1610-6

2.55 1.23

0.88

1 1/8 B-1810-6 0.97

1 1/4 -2000-6 3.63 1.62 1.09

1 1/2 -2400-6 4.25 1.97 1.34

2 -3200-6 5.88 2.66 1.81

Dimensions, mm

2 -2M0-6 35.6

12.9

1.7

3 -3M0-6 35.3

2.4

4 -4M0-6 37.3 13.7

6 -6M0-6 41.0 15.3 4.8

8 -8M0-6 43.2 16.2 6.4

10 -10M0-6 46.2 17.2 7.9

12 -12M0-6 51.2 22.8 9.5

14 -14M0-6

52.0

24.4

11.1

15 -15M0-6 11.9

16 -16M0-6 12.7

18 -18M0-6 53.5 15.1

20 -20M0-6

55.0 26.0

15.9

22 -22M0-6 18.3

25 -25M0-6 65.0 31.3

21.8

28

-28M0-6 85.0 36.6

B-28M0-6 65.4 31.6 24.6

30 -30M0-6 92.7 39.6 26.2

32 -32M0-6 97.3 42.0 28.6

38 -38M0-6 114 49.4 33.7

50 -50M0-6 146 65.0 45.2

Union

Ordering Numbers and Dimensions

■

See How to Order, below. Minimum order quantities may apply to certain materials and congurations.

■

Dimensions are for reference only and are subject to change. Unless noted otherwise, dimensions shown are for stainless

steel components and with Swagelok nuts nger-tight. For Swagelok nut dimensions, see page 57.

■

CAD templates are available on www.swagelok.com.

Straight Fittings

Unions

Union (Metric to Fractional)

D D

A

E

D Dx

A

E

F at

Tx

T

➀ Bored through.

Tube OD

Basic

Ordering

Number

Dimensions

T Tx, in. A D Dx E F

Dimensions, mm

2

1/8

1/4

-2M0-6-2

-2M0-6-4

35.2

38.6

12.9

12.8

15.3

1.7

12

14

3 1/8 -3M0-6-2 35.2 12.9 12.8 2.4 12

4

1/8

1/4

-4M0-6-2

-4M0-6-4

36.5

39.4

13.7

12.8

15.3

2.4

12

14

6

1/16

1/8

1/4

5/16

3/8

-6M0-6-1

-6M0-6-2

-6M0-6-4

-6M0-6-5

-6M0-6-6

34.3

38.5

41.0

42.3

43.2

15.3

8.6

12.8

15.3

16.2

16.8

1.3

2.4

4.8

4.8

4.8

14

14

14

14

16

8

1/4

3/8

-8M0-6-4

-8M0-6-6

42.3

44.3

16.2

15.3

16.9

4.8

6.4

15

16

10

1/8

1/4

5/16

3/8

-10M0-6-2

-10M0-6-4

-10M0-6-5

-10M0-6-6

41.8

44.5

45.1

45.9

17.2

12.8

15.3

16.2

16.9

2.4

4.8

6.4

7.1

18

12

1/4

5/16

3/8

1/2

-12M0-6-4

-12M0-6-5

-12M0-6-6

-12M0-6-8

47.0

47.8

48.4

51.2

22.8

15.3

16.2

16.9

22.9

4.8

6.4

7.1

9.5

22

14 1/2 -14M0-6-8 52.0 24.4 22.9 10.3 24

15 1/2 -15M0-6-8 52.0 24.4 22.9 10.3 24

16 5/8 -16M0-6-10 52.0 24.4 24.4 12.7 24

18 3/4 -18M0-6-12 53.5 24.4 24.4 15.1 27

20

1/2

1

-20M0-6-8

-20M0-6-16

55.0

62.8

26.0

22.9

31.3

10.3

15.9

30

35

25 1 -25M0-6-16 65.0 31.3 31.3 21.8 35

How to Order

Select a basic ordering number. Example -100-6

Add a material designator. Example: SS-100-6

Material Designator Material Designator

316 SS SS Alloy 2507 2507

Aluminum A Alloy C-276 HC

6-Moly 6MO Brass B

Alloy 400 M Carbon steel S

Alloy 600 INC PTFE T

Alloy 625 625

Titanium

(grade 4)

TI

Alloy 825 825

Refer to Installation Instructions, beginning on page 69.

Gaugeable Tube Fittings and Adapter Fittings 15

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBE

FITTINGS

Unions

Tx

T

D Dx

A

E

Reducing Union

Tube OD

Basic

Ordering

Number

Dimensions

T Tx A D Dx E

Dimensions, in.

1/8 1/16 -200-6-1 1.22 0.50 0.34 0.05

3/16

1/16

1/8

-300-6-1

-300-6-2

1.27

1.44

0.54

0.34

0.50

0.05

0.09

1/4

1/16

1/8

3/16

-400-6-1

-400-6-2

-400-6-3

1.35

1.52

1.55

0.60

0.34

0.50

0.54

0.05

0.09

0.12

5/16

1/8

1/4

-500-6-2

-500-6-4

1.56

1.66

0.64

0.50

0.60

0.09

0.19

3/8

1/16

1/8

1/4

5/16

-600-6-1

-600-6-2

-600-6-4

-600-6-5

1.44

1.61

1.70

1.74

0.66

0.34

0.50

0.60

0.64

0.05

0.09

0.19

0.25

1/2

1/8

1/4

3/8

-810-6-2

-810-6-4

-810-6-6

1.78

1.85

1.91

0.90

0.50

0.60

0.66

0.09

0.19

0.28

5/8

3/8

1/2

-1010-6-6

-1010-6-8

1.94

2.05

0.96

0.66

0.90

0.28

0.41

3/4

1/4

3/8

1/2

5/8

-1210-6-4

-1210-6-6

-1210-6-8

-1210-6-10

1.94

2.00

2.11

2.11

0.96

0.60

0.66

0.90

0.96

0.19

0.28

0.41

0.50

1

1/2

3/4

-1610-6-8

-1610-6-12

2.38 1.23

0.90

0.96

0.41

0.62

Dimensions, mm

3 2 -3M0-6-2M 35.3 12.9 12.9 1.7

6

2

3

4

-6M0-6-2M

-6M0-6-3M

-6M0-6-4M

38.6

38.6

39.4

15.3

12.9

12.9

13.7

1.7

2.4

2.4

8 6 -8M0-6-6M 42.3 16.2 15.3 4.8

10

6

8

-10M0-6-6M

-10M0-6-8M

44.5

45.1

17.2

15.3

16.2

4.8

6.4

12

6

8

10

-12M0-6-6M

-12M0-6-8M

-12M0-6-10M

47.0

47.8

48.7

22.8

15.3

16.2

17.2

4.8

6.4

7.9

14 12 -14M0-6-12M 48.8 24.4 22.8 6.4

15 12 -15M0-6-12M 48.8 24.4 22.8 6.4

16

10

12

-16M0-6-10M

-16M0-6-12M

49.5

52.0

24.4

17.2

22.8

7.9

9.5

18 12 -18M0-6-12M 53.5 24.4 22.8 9.5

25

18

20

-25M0-6-18M

-25M0-6-20M

61.0

62.3

31.3

24.4

26.0

15.1

15.9

30

18

20

25

-30M0-6-18M

-30M0-6-20M

-30M0-6-25M

75.4

75.4

80.1

39.6

24.4

26.0

31.3

15.1

15.9

21.8

32

18

20

25

-32M0-6-18M

-32M0-6-20M

-32M0-6-25M

77.8

77.8

82.3

42.0

24.4

26.0

31.3

15.1

15.9

21.8

38

20

25

30

-38M0-6-20M

-38M0-6-25M

-38M0-6-30M

87.5

92.0

105

49.4

26.0

31.3

39.6

15.9

21.8

26.2

Straight Fittings

Refer to Installation Instructions, beginning on page 69.

16 Tube Fittings

TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

Bulkhead Union

➀ Minimum panel thickness is 0.06 in.

D D

A

E

F atF at F at

Unions

Tube

OD

Basic

Ordering

Number

Dimensions

A D E F

Panel

Hole

Size

Max

Panel

Thickness

Dimensions, in.

1/16 -100-61 1.24 0.34 0.05 5/16 13/64 0.12

➀

1/8 -200-61 2.02 0.50 0.09 1/2 21/64

0.50

3/16 -300-61 2.11 0.54 0.12 9/16 25/64

1/4 -400-61 2.27 0.60 0.19 5/8 29/64 0.40

5/16 -500-61 2.39 0.64 0.25 11/16 33/64

0.44

3/8 -600-61 2.45 0.66 0.28 3/4 37/64

1/2 -810-61

2.80 0.90 0.41 15/16 49/64

0.50

5/8 -1010-61 2.86 0.96 0.50 1 1/16 57/64

3/4 -1210-61 3.11 0.96 0.62 1 3/16 1 1/64 0.66

1 -1610-61 3.77 1.23 0.88 1 5/8 1 21/64

0.75

1 1/4 -2000-61 4.85 1.62 1.09 1 7/8 1 41/64

1 1/2 -2400-61 5.48 1.97 1.34 2 1/4 1 61/64

2 -3200-61 7.10 2.66 1.81 2 3/4 2 41/64

Dimensions, mm

3 -3M0-61 51.3 12.9 2.4

14

8.3

12.7

4 -4M0-61 53.6 13.7 2.4 9.9

6 -6M0-61 57.7 15.3 4.8 16 11.5 10.2

8 -8M0-61 61.0 16.2 6.4 18 13.1

11.2

10 -10M0-61 63.7 17.2 7.9 22 16.3

12 -12M0-61 71.0 22.8 9.5 24 19.5

12.7

14 -14M0-61 72.5 24.4 11.1

27

22.5

15 -15M0-61 72.5 24.4 11.9

22.8

16 -16M0-61 72.5 24.4 12.7

18 -18M0-61 78.9 24.4 15.1 30 26.0 16.8

20 -20M0-61 84.5 26.0 15.9 35 29.0

19.0

25 -25M0-61 96.0 31.3 21.8 41 34.0

30 -30M0-61 124 39.6 26.2

50

40.5

32 -32M0-61 128 42.0 28.6 42.5

38 -38M0-61 145 49.4 33.7 60 50.5

Bulkhead Reducing Union (Metric to Fractional)

Tube OD

Basic

Ordering

Number

Dimensions

T Tx, in. A D Dx E F

Panel

Hole

Size

Max

Panel

Thickness

Dimensions, mm

6 1/8 -6M0-61-2 55.1 15.3 12.7 2.4 16 11.5 10.2

Straight Fittings

Bulkhead Reducing Union

D Dx

A

E

F atF at F at

Tx

Tube OD

Basic

Ordering

Number

Dimensions

T Tx A D Dx E F

Panel

Hole

Size

Max

Panel

Thickness

Dimensions, in.

1/8 1/16 -200-61-1 1.85 0.50 0.34 0.05 1/2 21/64 0.50

1/4 1/8 -400-61-2 2.17 0.60 0.50 0.09 5/8 29/64 0.40

3/8 1/4 -600-61-4 2.39 0.66

0.60 0.19

3/4 37/64 0.44

1/2 1/4 -810-61-4 2.63 0.90 15/16 49/64 0.50

T

Refer to Installation Instructions, beginning on page 69.

Gaugeable Tube Fittings and Adapter Fittings 17

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBE

FITTINGS

Male Connectors

NPT

➀ The E dimension is the minimum nominal opening. These ttings may have

a larger opening at the pipe/straight thread end.

D

A

E

F at

➀ The E dimension is the minimum nominal opening. These ttings may have

a larger opening at the pipe/straight thread end.

Tube

OD

NPT

Size

Basic

Ordering

Number

Dimensions

A D E

➀

F

Dimensions, in.

1/16

1/16

1/8

1/4

-100-1-1

-100-1-2

-100-1-4

0.94

1.03

1.22

0.34 0.05

5/16

7/16

9/16

1/8

1/16

1/8

1/4

3/8

1/2

-200-1-1

-200-1-2

-200-1-4

-200-1-6

-200-1-8

1.17

1.20

1.40

1.41

1.66

0.50 0.09

7/16

7/16

9/16

11/16

7/8

3/16

1/8

1/4

-300-1-2

-300-1-4

1.23

1.43

0.54 0.12

7/16

9/16

1/4

1/16

1/8

1/4

3/8

1/2

3/4

-400-1-1

-400-1-2

-400-1-4

-400-1-6

-400-1-8

-400-1-12

1.29

1.29

1.49

1.51

1.76

1.82

0.60

0.12

0.19

0.19

0.19

0.19

0.19

1/2

1/2

9/16

11/16

7/8

1 1/16

5/16

1/8

1/4

3/8

-500-1-2

-500-1-4

-500-1-6

1.34

1.52

1.54

0.64

0.19

0.25

0.25

9/16

9/16

11/16

3/8

1/8

1/4

3/8

1/2

3/4

1

-600-1-2

-600-1-4

-600-1-6

-600-1-8

-600-1-12

-600-1-16

1.39

1.57

1.57

1.82

1.88

2.14

0.66

0.19

0.28

0.28

0.28

0.28

0.28

5/8

5/8

11/16

7/8

1 1/16

1 3/8

1/2

1/8

1/4

3/8

1/2

3/4

1

-810-1-2

-810-1-4

-810-1-6

-810-1-8

-810-1-12

-810-1-16

1.53

1.71

1.71

1.93

1.99

2.25

0.90

0.19

0.28

0.38

0.41

0.41

0.41

13/16

13/16

13/16

7/8

1 1/16

1 3/8

5/8

1/4

3/8

1/2

3/4

-1010-1-4

-1010-1-6

-1010-1-8

-1010-1-12

1.74

1.74

1.93

1.99

0.96

0.28

0.38

0.47

0.50

15/16

15/16

15/16

1 1/16

3/4

3/8

1/2

3/4

1

-1210-1-6

-1210-1-8

-1210-1-12

-1210-1-16

1.80

1.99

1.99

2.25

0.96

0.41

0.47

0.62

0.62

1 1/16

1 1/16

1 1/16

1 3/8

7/8

1/2

3/4

1

-1410-1-8

-1410-1-12

-1410-1-16

1.99

1.99

2.25

1.02

0.47

0.62

0.72

1 3/16

1 3/16

1 3/8

1

1/2

3/4

1

-1610-1-8

-1610-1-12

-1610-1-16

2.26

2.26

2.45

1.23

0.47

0.62

0.88

1 3/8

1 1/8 1 B-1810-1-16 2.45 1.23 0.88 1 5/8

1 1/4

1

1 1/4

-2000-1-16

-2000-1-20

3.04 1.62

0.88

1.09

1 3/4

1 1/2 1 1/2 -2400-1-24 3.50 1.97 1.34 2 1/8

2 2 -3200-1-32 4.47 2.66 1.81 2 3/4

Tube

OD

NPT

Size

in.

Basic

Ordering

Number

Dimensions

A D E

➀

F

Dimensions, mm

2 1/8 -2M0-1-2 30.5 12.9 1.7 12

3

1/8

1/4

-3M0-1-2

-3M0-1-4

30.5

35.6

12.9 2.4

12

14

4

1/8

1/4

-4M0-1-2

-4M0-1-4

31.2

36.3

13.7 2.4

12

14

6

1/8

1/4

3/8

1/2

-6M0-1-2

-6M0-1-4

-6M0-1-6

-6M0-1-8

32.8

37.9

38.4

44.7

15.3 4.8

14

14

18

22

8

1/8

1/4

3/8

1/2

-8M0-1-2

-8M0-1-4

-8M0-1-6

-8M0-1-8

34.2

38.7

39.3

45.6

16.2

4.8

6.4

6.4

6.4

15

15

18

22

10

1/8

1/4

3/8

1/2

3/4

-10M0-1-2

-10M0-1-4

-10M0-1-6

-10M0-1-8

-10M0-1-12

36.3

40.9

40.9

46.5

48.0

17.2

4.8

7.1

7.9

7.9

7.9

18

18

18

22

27

12

1/8

1/4

3/8

1/2

3/4

-12M0-1-2

-12M0-1-4

-12M0-1-6

-12M0-1-8

-12M0-1-12

38.8

43.4

43.4

49.0

50.5

22.8

4.8

7.1

9.5

9.5

9.5

22

22

22

22

27

14

1/4

3/8

1/2

-14M0-1-4

-14M0-1-6

-14M0-1-8

44.1

44.1

49.0

24.4

7.1

9.5

11.1

24

15 1/2 -15M0-1-8 49.0 24.4 11.9 24

16

3/8

1/2

3/4

-16M0-1-6

-16M0-1-8

-16M0-1-12

44.1

49.0

50.5

24.4

9.5

11.9

12.7

24

24

27

18

1/2

3/4

-18M0-1-8

-18M0-1-12

50.5 24.4

11.9

15.1

27

20

1/2

3/4

-20M0-1-8

-20M0-1-12

52.3 26.0

11.9

15.9

30

22

3/4

1

-22M0-1-12

-22M0-1-16

52.3

57.1

26.0

15.9

18.3

30

35

25

1/2

3/4

1

-25M0-1-8

-25M0-1-12

-25M0-1-16

57.5

57.5

62.3

31.3

11.9

15.9

21.8

35

28

1

1 1/4

-28M0-1-16

-28M0-1-20

72.4

73.1

36.6 21.8

41

46

1

1 1/4

B-28M0-1-16

B-28M0-1-20

75.0

77.3

31.6 24.6

41

46

30 1 1/4 -30M0-1-20 77.2 39.6 26.2 46

32 1 1/4 -32M0-1-20 79.6 42.0 28.6 46

38 1 1/2 -38M0-1-24 91.6 49.4 33.7 55

Straight Fittings

Refer to Installation Instructions, beginning on page 69.

18 Tube Fittings

TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

See page 9 for thread specications.

Male Connectors

ISO/BSP Tapered Thread (RT)

D

A

E

F at

➀ The E dimension is the minimum nominal opening. These ttings may have

a larger opening at the pipe/straight thread end.

➀ The E dimension is the minimum nominal opening. These ttings may have

a larger opening at the pipe/straight thread end.

Tube

OD

ISO

Thread

Size

Basic

Ordering

Number

Dimensions

A D E

➀

F

Dimensions, in.

1/8

1/8

1/4

-200-1-2RT

-200-1-4RT

1.20

1.40

0.50 0.09

7/16

9/16

1/4

1/8

1/4

3/8

1/2

-400-1-2RT

-400-1-4RT

-400-1-6RT

-400-1-8RT

1.29

1.49

1.51

1.76

0.60 0.19

1/2

9/16

11/16

7/8

5/16

1/8

1/4

-500-1-2RT

-500-1-4RT

1.34

1.52

0.64

0.19

0.25

9/16

3/8

1/8

1/4

3/8

1/2

3/4

-600-1-2RT

-600-1-4RT

-600-1-6RT

-600-1-8RT

-600-1-12RT

1.39

1.57

1.57

1.82

1.88

0.66

0.19

0.28

0.28

0.28

0.28

5/8

5/8

11/16

7/8

1 1/16

1/2

1/4

3/8

1/2

3/4

-810-1-4RT

-810-1-6RT

-810-1-8RT

-810-1-12RT

1.71

1.71

1.93

1.99

0.90

0.28

0.38

0.41

0.41

13/16

13/16

7/8

1 1/16

5/8 1/2 -1010-1-8RT 1.93 0.96 0.47 15/16

3/4

3/4

1

-1210-1-12RT

-1210-1-16RT

1.99

2.25

0.96 0.62

1 1/16

1 3/8

1

3/4

1

-1610-1-12RT

-1610-1-16RT

2.26

2.45

1.23

0.63

0.88

1 3/8

1 1/4 1 1/4 -2000-1-20RT 3.04 1.62 1.09 1 3/4

Tube

OD

ISO

Thread

Size, in.

Basic

Ordering

Number

Dimensions

A D E

➀

F

Dimensions, mm

2 1/8 -2M0-1-2RT 30.5 12.9 1.7 12

3

1/8

1/4

-3M0-1-2RT

-3M0-1-4RT

30.5

35.6

12.9 2.4

12

14

4

1/8

1/4

-4M0-1-2RT

-4M0-1-4RT

31.2

36.3

13.7 2.4

12

14

6

1/8

1/4

3/8

1/2

-6M0-1-2RT

-6M0-1-4RT

-6M0-1-6RT

-6M0-1-8RT

32.8

37.9

38.4

44.7

15.3 4.8

14

14

18

22

8

1/8

1/4

3/8

1/2

-8M0-1-2RT

-8M0-1-4RT

-8M0-1-6RT

-8M0-1-8RT

34.2

38.7

39.2

45.6

16.2

4.8

6.4

6.4

6.4

15

15

18

22

10

1/8

1/4

3/8

1/2

3/4

-10M0-1-2RT

-10M0-1-4RT

-10M0-1-6RT

-10M0-1-8RT

-10M0-1-12RT

36.3

40.9

40.9

46.5

48.0

17.2

4.8

7.1

7.9

7.9

7.9

18

18

18

22

27

12

1/4

3/8

1/2

3/4

-12M0-1-4RT

-12M0-1-6RT

-12M0-1-8RT

-12M0-1-12RT

43.4

43.4

49.0

50.5

22.8

7.1

9.5

9.5

9.5

22

22

22

27

14

1/4

3/8

-14M0-1-4RT

-14M0-1-6RT

44.1

44.1

24.4

7.1

9.5

24

15 1/2 -15M0-1-8RT 49.0 24.4 11.9 24

16

1/4

3/8

1/2

3/4

-16M0-1-4RT

-16M0-1-6RT

-16M0-1-8RT

-16M0-1-12RT

44.1

44.1

49.0

50.5

24.4

7.1

9.5

11.9

12.7

24

24

24

27

18

1/2

3/4

-18M0-1-8RT

-18M0-1-12RT

50.5 24.4

11.9

15.1

27

20

1/2

3/4

-20M0-1-8RT

-20M0-1-12RT

52.3 26.0

11.9

15.9

30

22

3/4

1

-22M0-1-12RT

-22M0-1-16RT

52.3

57.1

26.0

15.9

18.3

30

35

25

1/2

3/4

1

-25M0-1-8RT

-25M0-1-12RT

-25M0-1-16RT

57.5

57.5

62.3

31.3

11.9

15.9

21.8

35

28

1

1 1/4

-28M0-1-16RT

-28M0-1-20RT

72.4

73.1

36.6 21.8

41

46

1

1 1/4

B-28M0-1-16RT

B-28M0-1-20RT

75.0

77.3

31.6 22.2

41

46

30 1 1/4 -30M0-1-20RT 77.2 39.6 26.2 46

32 1 1/4 -32M0-1-20RT 79.6 42.0 28.6 46

38 1 1/2 -38M0-1-24RT 91.6 49.4 33.7 55

Straight Fittings

Refer to Installation Instructions, beginning on page 69.

Gaugeable Tube Fittings and Adapter Fittings 19

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBE

FITTINGS

See page 9 for thread specications.

ISO/BSP parallel gaskets are available. See page 60.

Male Connectors

ISO/BSP Parallel Thread (RS)

D

A

E

F at

➀ The E dimension is the minimum nominal opening. These ttings may have

a larger opening at the pipe/straight thread end.

➀ The E dimension is the minimum nominal opening. These ttings may have

a larger opening at the pipe/straight thread end.

Tube

OD

ISO

Thread

Size

Basic

Ordering

Number

Dimensions

A D E

➀

F

Dimensions, in.

1/8

1/8

1/4

3/8

-200-1-2RS

-200-1-4RS

-200-1-6RS

1.31

1.50

1.53

0.50 0.09

9/16

3/4

7/8

1/4

1/8

1/4

3/8

1/2

-400-1-2RS

-400-1-4RS

-400-1-6RS

-400-1-8RS

1.40

1.59

1.62

1.70

0.60

0.16

0.19

0.19

0.19

9/16

3/4

7/8

1 1/16

3/8

1/8

1/4

3/8

1/2

-600-1-2RS

-600-1-4RS

-600-1-6RS

-600-1-8RS

1.49

1.65

1.68

1.76

0.66

0.16

0.23

0.28

0.28

5/8

3/4

7/8

1 1/16

1/2

1/4

3/8

1/2

-810-1-4RS

-810-1-6RS

-810-1-8RS

1.76

1.79

1.87

0.90

0.23

0.31

0.41

13/16

7/8

1 1/16

3/4

1/2

3/4

-1210-1-8RS

-1210-1-12RS

1.92

2.05

0.96

0.47

0.62

1 1/16

1 5/16

1

1/2

3/4

1

-1610-1-8RS

-1610-1-12RS

-1610-1-16RS

2.19

2.27

2.35

1.23

0.47

0.63

0.78

1 3/8

1 3/8

1 5/8

Tube

OD

ISO

Thread

Size, in.

Basic

Ordering

Number

Dimensions

A D E

➀

F

Dimensions, mm

2 1/8 -2M0-1-2RS 33.3 12.9 1.7 14

3

1/8

1/4

-3M0-1-2RS

-3M0-1-4RS

33.3

38.1

12.9 2.4

14

19

4 1/8 -4M0-1-2RS 34.0 13.7 2.4 14

6

1/8

1/4

3/8

1/2

-6M0-1-2RS

-6M0-1-4RS

-6M0-1-6RS

-6M0-1-8RS

35.6

40.4

41.1

43.2

15.3

4.0

4.8

4.8

4.8

14

19

22

27

8

1/8

1/4

3/8

1/2

-8M0-1-2RS

-8M0-1-4RS

-8M0-1-6RS

-8M0-1-8RS

36.6

41.4

42.2

44.2

16.2

4.0

5.9

6.4

6.4

15

19

22

27

10

1/4

3/8

1/2

-10M0-1-4RS

-10M0-1-6RS

-10M0-1-8RS

42.2

42.9

45.0

17.2

5.9

7.9

7.9

19

22

27

12

1/4

3/8

1/2

3/4

-12M0-1-4RS

-12M0-1-6RS

-12M0-1-8RS

-12M0-1-12RS

44.5

45.5

47.5

52.1

22.8

5.9

7.9

9.5

9.5

22

22

27

35

14

3/8

1/2

-14M0-1-6RS

-14M0-1-8RS

43.9

47.5

24.4

7.9

11.1

24

27

15

3/8

1/2

3/4

-15M0-1-6RS

-15M0-1-8RS

-15M0-1-12RS

45.5

47.5

52.8

24.4

7.9

11.9

11.9

24

27

35

16

3/8

1/2

3/4

-16M0-1-6RS

-16M0-1-8RS

-16M0-1-12RS

45.5

47.5

52.8

24.4

7.9

11.9

12.7

24

27

35

18

1/2

3/4

-18M0-1-8RS

-18M0-1-12RS

48.8

52.1

24.4

11.9

15.1

27

35

20

1/2

3/4

-20M0-1-8RS

-20M0-1-12RS

50.5

52.6

26.0

11.9

15.9

30

35

22

3/4

1

-22M0-1-12RS

-22M0-1-16RS

52.6

54.9

26.0

15.9

18.3

35

41

25

3/4

1

-25M0-1-12RS

-25M0-1-16RS

57.7

59.7

31.3

15.9

19.8

35

41

28

1

1 1/4

-28M0-1-16RS

-28M0-1-20RS

69.9

72.9

36.6

19.8

21.8

41

50

1

1 1/4

B-28M0-1-16RS

B-28M0-1-20RS

72.5

77.1

31.6

19.8

24.6

41

54

30 1 1/4 -30M0-1-20RS 76.7 39.6 26.2 50

32 1 1/4 -32M0-1-20RS 79.2 42.0 28.6 50

38 1 1/2 -38M0-1-24RS 90.9 49.4 31.8 55

Straight Fittings

Refer to Installation Instructions, beginning on page 69.

20 Tube Fittings

TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERS

INSTRUMENT

MANIFOLD

SYSTEMS

MEASUREMENT

DEVICES

REFERENCES

MEDIUM- HIGH-

PRESSURE

See page 9 for thread specications.

ISO/BSP parallel gaskets are available. See page 60.

Male Connectors

ISO/BSP Parallel Thread (RP)

D

A

E

F at

Bored-Through Fittings for Thermocouples,

Dip Tubes, and Heat Exchanger Tees

Swagelok bored-through male connectors accommodate

thermocouples or dip tubes. Most male connectors are

available as a bored-through tting, but male connectors

whose pipe thread end is small relative to the tube tting

end—such as -600-1-2 or -8M0-1-2RT—cannot be bored

through.

Swagelok bored-through reducers and standard Swagelok

tees can be used to create a heat exchanger tee.

To order bored-through ttings, add BT to the ordering

number. Example: SS-400-1-4BT

Bored-through ttings have a reduced pressure rating.

In general, we have multiplied the allowable working

pressure of the tubing, as found on the Tubing Data Sheet,

MS-01-107, by the factors in the table to the right.

➀ The E dimension is the minimum nominal opening. These ttings may have

a larger opening at the pipe/straight thread end.

➀ The E dimension is the minimum nominal opening. These ttings may have

a larger opening at the pipe/straight thread end.

Tube

OD

ISO

Thread

Size

Basic

Ordering

Number

Dimensions

A D E

➀

F

Dimensions, in.

1/8

1/8

1/4

-200-1-2RP

-200-1-4RP

1.31

1.50

0.50 0.09

9/16

3/4

1/4

1/8

1/4

-400-1-2RP

-400-1-4RP

1.40

1.59

0.60

0.16

0.19

9/16

3/4

1/2

3/8

1/2

-810-1-6RP

-810-1-8RP

1.79

1.87

0.90

0.31

0.41

7/8

1 1/16

3/4

1/2

3/4

-1210-1-8RP

-1210-1-12RP

1.92

2.05

0.96

0.47

0.62

1 1/16

1 5/16

1 1 -1610-1-16RP 2.35 1.23 0.78 1 5/8

Tube

OD

ISO

Thread

Size, in.

Basic

Ordering

Number

Dimensions

A D E

➀

F

Dimensions, mm

3

1/8

1/4

-3M0-1-2RP

-3M0-1-4RP

33.3

38.1

12.9 2.4

14

19

4 1/8 -4M0-1-2RP 34.0 13.7 2.4 14

6

1/8

1/4

3/8

1/2

-6M0-1-2RP

-6M0-1-4RP

-6M0-1-6RP

-6M0-1-8RP

35.6

40.4

41.2

43.2

15.3

4.0

4.8

4.8

4.8

14

19

22

27

8

1/8

1/4

3/8

1/2

-8M0-1-2RP

-8M0-1-4RP

-8M0-1-6RP

-8M0-1-8RP

36.5

41.3

41.9

44.1

16.2

4.0

5.9

6.4

6.4

15

19

22

27

10

1/4

3/8

1/2

-10M0-1-4RP

-10M0-1-6RP

-10M0-1-8RP

42.2

42.9

45.0

17.2

5.9

7.9

7.9