HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 1 of 21

Instructions for Use

This Asbestos Management – Minor Works Safe Work Method Statement (SWMS) template has been prepared

to assist JCU employees and contractors in the planning and safe execution of minor works involving asbestos

containing materials.

The HSE-PRO-006 Asbestos Management Procedure defines minor works as “work that has potential to disturb

non-friable ACM but does not involve removal of ACM. Any work that has potential to disturb friable ACM is not

considered Minor Works.”

Minor works can only be undertaken by a competent person (employee or contractor). An Asbestos Management

– Minor Works SWMS must be prepared and an Asbestos Permit issued prior to commencing the works. Closing

out a permit for minor works must include a visual inspection of the work area by the Permit Issuer.

This template includes pre-populated tables for the following tasks involving non-friable ACM:

• Making penetrations

• Installing or removing fixings on or through non-friable ACM

• Painting (and preparation for painting) of non-friable ACM

• Pulling cables/wires through non-friable ACM conduit

• Polishing of asbestos vinyl flooring

To use this template:

1. Fill in Section 1 with your details

2. Fill in Section 2 with the details of the work

3. In section 3, delete the tables that do not apply to your work and leave the table that does apply

4. In section 3, check the existing details and add any other task specific information and controls

5. Add any other identified hazards and controls to reduce risk e.g. for work at height and electrical hazards

6. In section 5, all participants to sign the acknowledgement

Person authorising the asbestos permit must review and approve the SWMS.

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 2 of 21

SECTION 1: DETAILS OF PERMIT ISSUER (PERSON UNDERTAKING THE WORK)

Organisation/Company:

Company Phone Number:

Name of Person Responsible

for the Work:

Mobile Number:

Names of Person(s)

Consulted in preparing this

SWMS:

Contact Number(s):

SECTION 2: DETAILS OF THE WORK

Reason for and description of

works:

Location of works

(Campus/Building/Room):

Licences Required:

Not required for minor works

Permits Required:

JCU Asbestos Permit

Training Required:

JCU Employee or Contractor Induction

Asbestos Awareness Training

Construction Safety Induction (White Card)

Emergency Planning:

As per JCU induction

First Aid Kits to be available

Controls:

Separation of work area and restricted access

Signage & barricades

Respiratory Protection (see details below)

Dust suppression

Decontamination of plant and personnel

Containment and disposal of waste

Ventilation Isolated

Relevant Safety Laws & Codes

of Practice

Work Health & Safety Act 2011

Work Health & Safety Regulation 2011

How to Manage and Control Asbestos in the Workplace Code of Practice 2011

How to Safely Remove Asbestos Code of Practice 2011

How to Manage Work Health and Safety Risks Code of Practice 2011

Managing the risk of falls at Workplaces Code of Practice 2011

Hazardous Manual Tasks Code of Practice 2011

Relevant Aust. Standards

AS 1337 (eye protection); AS 2210 (foot protection); AS 1716 (respiratory protection) ; AS 1715 (selection of respiratory protection)

Site Specific Requirements

Comply with all reasonable directions from JCU Estate Directorate and Workplace Health & Safety personnel.

JCU Asbestos Management Standard

JCU Asbestos Register

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 3 of 21

SECTION 3: SWMS

Drilling Non-Friable ACM

Notes:

This method describes the use of a thickened substance (e.g. hair gel, shaving cream or wallpaper paste) to supress and contain

asbestos dust during low speed drilling of non-friable ACM (e.g. cement sheet or bitumen board). If drilling overhead, a disposable

cup should be used to hold the substance to the surface, then drill through the cup. The cup may need to be cut-down so that just

the bottom of the cup is used. If unfamiliar with this process the method should be practiced on non-ACM material until all dust and

debris can be reliably contained and the person is familiar and confident with decontamination.

If an asbestos HEPA vacuum cleaner is available, this can be used to shadow vacuum (very close to the hole) instead of using the

thickening substance.

If the hole does not need to be neat, a nail or punch can be used as this generates less fine dust compared to drilling. Care should

be taken to avoid scattering pieces of debris from the back side of the hole.

If a large hole is needed, it is difficult to control the dust from a hole saw, preference is to trace the outline then drill or punch small

holes around the edge then break the bridging pieces. This may seem “messier” but less fine airborne dust is created, reducing the

risk of exposure.

Tools and Equipment to be

used:

Drill, hand powered or low speed electric

Drill bit (i.e. masonry bit)

Warning signs and/or danger tape

Asbestos HEPA Vacuum Cleaner (if drilling dry)

Duct tape

Task lighting (e.g. head torch)

Disposable wet wipes or rags & bucket of water

Misting spray bottle with PVA solution

Thickened substance (e.g. hair gel, shaving cream or wallpaper paste)

Disposable cup

200um plastic drop sheet

Asbestos waste bags (200um plastic with Asbestos Warning)

Respiratory Protection:

Half Face P2 Respirator (disposable or reusable)

Each worker to be fit tested (AS1715 method)

Fit check to be performed prior to commencing work

Other PPE:

Disposable coveralls (optional)

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 4 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Job Preparation

Assemble all tools and equipment.

Erect danger tape & Signage. Secure area by closing/locking doors to exclude

unauthorised persons from the work area. If back surface of material being

drilled is accessible then this area must also be segregated.

Use plastic sheeting to cover any surfaces that could become contaminated,

secure edges of sheeting with duct tape.

Tape both the point to be drilled and the exit point, if accessible, with duct tape

to prevent edges crumbling.

Turn off or seal ventilation/air-conditioning.

If outside avoid working in excessive wind.

Low

Drilling

Exposure to

airborne

asbestos

Respiratory protection to be worn.

Cover the drill entry and exit points (if accessible) with a generous amount of

Thickened Substance (paste). If necessary, use disposable cup to keep in

place.

Drill through the paste.

Use damp rag or wet wipe to clean the paste from drilled surfaces and drill bit,

place wipe into asbestos waste bag.

Seal cut edges with PVA solution or paint.

If a cable is to be passed though, insert a sleeve to protect the inner edge of

the hole.

Low

Electrical

Hazards

Work at

Height

Other:

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 5 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Decontaminate area and

equipment

Exposure to

airborne

asbestos

Clean equipment with wet wipes or damp rags.

If using a bucket of water, do not resoak used rags in the bucket as this will

contaminate the water. Instead, either fold the rag so a clean surface is

exposed or use a fresh rag.

Lightly spray drop sheet with PVA solution then roll or fold for disposal.

Place debris, used rags, plastic sheeting and other waste in the asbestos

waste bag.

Visually inspect the work area to ensure no visible dust or debris remains.

Low

Personal

decontamination

Exposure to

airborne

asbestos

If using coveralls, take coveralls off by turning inside out to contain any surface

contamination. Place into asbestos waste bag.

Remove respiratory protection. If disposable, place in asbestos waste bag. If

reusable, clean with wet wipe and store in clean container.

Low

Waste Transport and

Disposal

Exposure to

airborne

asbestos

Dry materials should not be placed in asbestos waste bag, pre-wet with PVA

solution to suppress dust.

Wet wipe the external surfaces of the asbestos waste bag to remove any

adhering dust.

Do not fill the bag more than two thirds full to allow room to seal.

Carefully expel excess air from Asbestos Waste Bag, twist top then bend over

to form a “goose neck” wrap tightly with Duct tape to seal.

Place the first bag into a second asbestos waste bag to “Double bag”. Twist,

goose neck and tape seal.

Less than 250 kg of asbestos waste can be transported without a regulated

waste licence. If more than 250 kg a licenced contractor must be used.

Transport the double bagged waste to a waste disposal site approved by the

local council (in Townsville the

Stuart, Hervey Range and Jensen waste

facilities will accept Asbestos waste between 7:30 am and 4:30 pm).

Low

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 6 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Clearance

Exposure to

airborne

asbestos

JCU Permit Authorising Person to perform inspection to confirm area is free

from visible dust or debris from the work.

Signage and danger tape to be removed after satisfactory inspection.

Permit sign off

Area may be reoccupied.

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 7 of 21

Installing or Removing Fixings on or Through Non-Friable ACM

Notes:

This method describes the use of a thickened substance (e.g. hair gel, shaving cream or wallpaper paste) to supress and contain

asbestos dust during installation or removal of fixings. If unfamiliar with this process the method should be practiced on non-ACM

material until all dust and debris can be reliably contained and the person is familiar and confident with decontamination.

If an asbestos HEPA vacuum cleaner is available, this can be used to shadow vacuum (very close to the fixing) instead of using

the thickening substance.

Tools and Equipment to be

used:

Fixings (Screws, nails etc.)

Low speed drill driver (if using screws)

Warning signs and/or danger tape

Asbestos HEPA Vacuum Cleaner (if installing dry)

Duct tape

Task lighting (e.g. head torch)

Disposable wet wipes or rags & bucket of water

Misting spray bottle with PVA solution

Thickened substance (e.g. hair gel, shaving cream or wallpaper paste)

200um plastic drop sheet

Asbestos waste bags (200um plastic with Asbestos Warning)

Respiratory Protection:

Half Face P2 Respirator (disposable or reusable)

Each worker to be fit tested (AS1715 method)

Fit check to be performed prior to commencing work

Other PPE:

Disposable coveralls (optional)

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Job Preparation

Assemble all tools and equipment.

Erect danger tape & Signage. Secure area by closing/locking doors to exclude

unauthorised persons from the work area. If back surface of material is

accessible then this area must also be segregated.

Use plastic sheeting to cover any surfaces that could become contaminated,

secure edges of sheeting with duct tape.

Turn off or seal ventilation/air-conditioning.

If outside avoid working in excessive wind.

Low

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 8 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Installing Fixing

Exposure to

airborne

asbestos

Respiratory protection to be worn.

Cover the fixing entry and exit points (if accessible) with a generous amount of

Thickened Substance (paste).

Install fixing slowly through the paste.

Use damp rag or wet wipe to clean the paste from surfaces, place wipe into

asbestos waste bag.

Low

Electrical

Hazards

Work at

Height

Other:

Removing Fixings

Exposure to

airborne

asbestos

Respiratory protection to be worn.

Cover the fixing entry and exit points (if accessible) with a generous amount of

Thickened Substance (paste).

If penetration of fixing through ACM is not accessible for applying paste, spray

or drizzle PVA solution to wet the fixing during removal.

Remove fixing slowly through the paste.

Use damp rag or wet wipe to clean the paste from surfaces, place fixing and

wipe into asbestos waste bag.

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 9 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Decontaminate area and

equipment

Exposure to

airborne

asbestos

Clean equipment with wet wipes or damp rags.

If using a bucket of water, do not resoak used rags in the bucket as this will

contaminate the water. Instead, either fold the rag so a clean surface is

exposed or use a fresh rag.

Lightly spray drop sheet with PVA solution then roll or fold for disposal.

Place debris, used rags, plastic sheeting and other waste in the asbestos

waste bag.

Visually inspect the work area to ensure no visible dust or debris remains.

Low

Personal

decontamination

Exposure to

airborne

asbestos

If using coveralls, take coveralls off by turning inside out to contain any surface

contamination. Place into asbestos waste bag.

Remove respiratory protection. If disposable, place in asbestos waste bag. If

reusable, clean with wet wipe and store in clean container.

Low

Waste Transport and

Disposal

Exposure to

airborne

asbestos

Dry materials should not be placed in asbestos waste bag, pre-wet with PVA

solution to suppress dust.

Wet wipe the external surfaces of the asbestos waste bag to remove any

adhering dust.

Do not fill the bag more than two thirds full to allow room to seal.

Carefully expel excess air from Asbestos Waste Bag, twist top then bend over

to form a “goose neck” wrap tightly with Duct tape to seal.

Place the first bag into a second asbestos waste bag to “Double bag”. Twist,

goose neck and tape seal.

Less than 250 kg of asbestos waste can be transported without a regulated

waste licence. If more than 250 kg a licenced contractor must be used.

Transport the double bagged waste to a waste disposal site approved by the

local council (in Townsville the

Stuart, Hervey Range and Jensen waste

facilities will accept Asbestos waste between 7:30 am and 4:30 pm).

Low

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 10 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Clearance

Exposure to

airborne

asbestos

JCU Permit Authorising Person to perform inspection to confirm area is free

from visible dust or debris from the work.

Signage and danger tape to be removed after satisfactory inspection.

Permit sign off.

Area may be reoccupied.

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 11 of 21

Painting (and preparation for painting)

Notes:

This method describes the process for sealing, painting, coating and cleaning non-friable ACM (e.g. Asbestos cement products).

This process should only be carried out on ACM that is in good condition. Under no circumstances should ACM be water blasted or

dry sanded in preparation for painting. If sanding is required consider removing the ACM and replacing with a non-asbestos

product. If wet sanding is performed the runoff must be captured and filtered, or all runoff disposed of in asbestos waste bag.

Tools and Equipment to be

used:

Clean rags & bucket of water

Warning signs and/or danger tape

Duct tape

Hand scraper (optional)

Sugar soap (optional)

Misting spray bottle with PVA solution

200um plastic drop sheet

Asbestos waste bags (200um plastic with Asbestos Warning)

Respiratory Protection:

Half Face P2 Respirator (disposable or reusable)

Each worker to be fit tested (AS1715 method)

Fit check to be performed prior to commencing work

**Other respiratory protection may be required to

control vapour or mist from painting**

Other PPE:

Disposable coveralls

Cleanable boots (no laces)

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Job Preparation

Assemble all tools and equipment.

Erect danger tape & Signage. Secure area by closing/locking doors to exclude

unauthorised persons from the work area.

Use plastic sheeting to cover any surfaces that could become contaminated,

secure edges of sheeting with duct tape. As far as practicable setup drop

sheets to contain runoff.

Turn off or seal ventilation/air-conditioning.

If outside avoid working in excessive wind.

Low

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 12 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Cleaning Surfaces to be

Painted

Exposure to

airborne

asbestos

Respiratory protection and coveralls to be worn.

Surfaces to be kept damp during cleaning, avoid excessive use of water to

minimise runoff.

Use a scraper to gently remove any loose flakes of old paint.

Wipe the surfaces clean with damp rags, sugar soap may assist to prepare the

surface. Do not resoak used rags in the bucket, as this will contaminate the

water. Instead, either fold the rag so a clean surface is exposed or use another

rag.

Wipe surfaces with a dry rag to remove dirty water from the surface.

Low

Electrical

Hazards

Work at

Height

Other:

Painting and

sealing

Exposure to

airborne

asbestos

When spray painting, only use low pressure airless spray equipment.

When using a roller or brush, for the first coat apply lightly to avoid abrasion of

the ACM surface.

Low

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 13 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Decontaminate area and

equipment

Exposure to

airborne

asbestos

Clean equipment with wet wipes or damp rags.

If using a bucket of water, do not resoak used rags in the bucket as this will

contaminate the water. Instead, either fold the rag so a clean surface is

exposed or use a fresh rag.

Place debris, used rags, plastic sheeting and other waste in the asbestos waste

bag.

Visually inspect the work area to ensure no visible dust or debris remains.

Low

Personal

decontamination

Exposure to

airborne

asbestos

Take coveralls off by turning inside out to contain any surface contamination.

Place into asbestos waste bag.

Remove respiratory protection. If disposable, place in asbestos waste bag. If

reusable, clean with wet wipe and store in clean container.

Low

Waste Transport and

Disposal

Exposure to

airborne

asbestos

Dry materials should not be placed in asbestos waste bag, pre-wet with PVA

solution to suppress dust.

Wet wipe the external surfaces of the asbestos waste bag to remove any

adhering dust.

Do not fill the bag more than two thirds full to allow room to seal.

Carefully expel excess air from Asbestos Waste Bag, twist top then bend over

to form a “goose neck” wrap tightly with Duct tape to seal.

Place the first bag into a second asbestos waste bag to “Double bag”. Twist,

goose neck and tape seal.

Less than 250 kg of asbestos waste can be transported without a regulated

waste licence. If more than 250 kg a licenced contractor must be used.

Transport the double bagged waste to a waste disposal site approved by the

local council (in Townsville the

Stuart, Hervey Range and Jensen waste

facilities will accept Asbestos waste between 7:30 am and 4:30 pm).

Low

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 14 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Clearance

Exposure to

airborne

asbestos

JCU Permit Authorising Person to perform inspection to confirm area is free

from visible dust or debris from the work.

Signage and danger tape to be removed after satisfactory inspection.

Permit sign off.

Area may be reoccupied.

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 15 of 21

Pulling Cables Through Non-Friable ACM Conduit

Notes:

This method describes the process for installing or removing cables in asbestos cement conduit or cable pits.

As far as is practicable, alternative (non-asbestos) conduits should be used or installed for use rather than reusing asbestos

conduits.

Tools and Equipment to be

used:

Cable slipping compound

Clean rags & bucket of water

Warning signs and/or danger tape

Duct tape

spray bottle with PVA solution

200um plastic sheeting

Asbestos waste bags (200um plastic with Asbestos Warning)

Asbestos vacuum cleaner (optional)

Respiratory Protection:

Half Face P2 Respirator (disposable or reusable)

Each worker to be fit tested (AS1715 method)

Fit check to be performed prior to commencing work

Other PPE:

Disposable coveralls

Cleanable boots (no laces)

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Job Preparation

Assemble all tools and equipment.

Erect danger tape & Signage. Secure area by closing/locking doors to

exclude unauthorised persons from the work area.

Use plastic sheeting to cover any surfaces that could become contaminated,

secure edges of sheeting with duct tape. Use plastic sheeting below

conduits before pulling cables through.

Turn off or seal ventilation/air-conditioning.

If outside avoid working in excessive wind.

Low

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 16 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Removal or Installation of

Cables

Exposure to

airborne

asbestos

Respiratory protection and coveralls to be worn.

Wet down the equipment and apply adequate cable slipping compound to

the conduits/ducts throughout the process.

Clean all ropes, rods or snakes used to pull cables after use. Cleaning

should be undertaken close to the point(s) where the cables exit from the

conduits/ducts.

Do not resoak used rags in the bucket, as this will contaminate the water.

Instead, either fold the rag so a clean surface is exposed or use another rag.

Ropes used for cable pulling must have a smooth surface that can easily be

cleaned.

Metal stockings must not be used when pulling cables through asbestos

cement conduits.

Compressed air darts must not be used to pull cables through asbestos

cement conduits/ducts.

Low

Electrical

Hazards

Work at Height

Other:

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 17 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Decontaminate area and

equipment

Exposure to

airborne

asbestos

Clean equipment with wet wipes or damp rags.

If using a bucket of water, do not resoak used rags in the bucket as this will

contaminate the water. Instead, either fold the rag so a clean surface is

exposed or use a fresh rag.

Wet wipe around the end of the conduit, sections of exposed cable and the

pulling eye at the completion of the cable pulling operation.

If the rope or cable passes through any rollers, these must also be wet wiped

after use.

Wet wipe the external surface of excess cable pulled through the

conduit/duct, as close as possible to the exit point from the conduit, before it

is removed from the work site.

Carefully roll or fold any plastic sheeting used to cover any surface within the

asbestos work area, so as not to spill any dust or debris that has been

collected.

If required, use damp rags or an asbestos vacuum cleaner to clean any

remaining visibly contaminated sections of the asbestos work area.

Place all debris, used rags, plastic sheeting and other waste in the asbestos

waste bag.

Wet wipe the external surfaces of the asbestos waste bags to remove any

adhering dust before they are removed from the asbestos work area.

Visually inspect the work area to ensure no visible dust or debris remains.

Low

Personal

decontamination

Exposure to

airborne

asbestos

Take coveralls off by turning inside out to contain any surface contamination.

Place into asbestos waste bag.

Remove respiratory protection. If disposable, place in asbestos waste bag.

If reusable, clean with wet wipe and store in clean container.

Low

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 18 of 21

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Waste Transport and

Disposal

Exposure to

airborne

asbestos

Dry materials should not be placed in asbestos waste bag, pre-wet with PVA

solution to suppress dust.

Wet wipe the external surfaces of the asbestos waste bag to remove any

adhering dust.

Do not fill the bag more than two thirds full to allow room to seal.

Carefully expel excess air from Asbestos Waste Bag, twist top then bend

over to form a “goose neck” wrap tightly with Duct tape to seal.

Place the first bag into a second asbestos waste bag to “Double bag”. Twist,

goose neck and tape seal.

Less than 250 kg of asbestos waste can be transported without a regulated

waste licence. If more than 250 kg a licenced contractor must be used.

Transport the double bagged waste to a waste disposal site approved by the

local council (in Townsville the

Stuart, Hervey Range and Jensen waste

facilities will accept Asbestos waste between 7:30 am and 4:30 pm).

Low

Clearance

Exposure to

airborne

asbestos

JCU Permit Authorising Person to perform inspection to confirm area is free

from visible dust or debris from the work.

Signage and danger tape to be removed after satisfactory inspection.

Permit sign off.

Area may be reoccupied.

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 19 of 21

Polishing Asbestos Vinyl Flooring

Notes:

This method describes the process for polishing asbestos vinyl floor coverings.

Asbestos vinyl floors must not be cut back, sanded or otherwise abraded.

Asbestos vinyl floors may be cleaned with a neutral all-purpose cleaner.

Asbestos vinyl floors should be coated with a good quality vinyl floor sealant.

Tools and Equipment to be

used:

Floor polishing equipment

No specialised equipment required

Respiratory Protection:

If these methods are correctly implemented, personal

protective equipment should not be necessary.

Other PPE: Not required

Tasks / Process Potential

Hazards

Control Measures Risk Rating

(with controls)

Person

responsible for

Controls

Floor Polishing

Exposure to

airborne

asbestos

Inspect flooring for damage prior to work. Asbestos containing sheet vinyls

with fibrous backing layers must not be polished if the fibrous backing layer is

showing. Report damage to JCU Estates Directorate.

Check flooring to ensure sufficient surface coating/sealant finish prior to dry

buffing.

Low

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 20 of 21

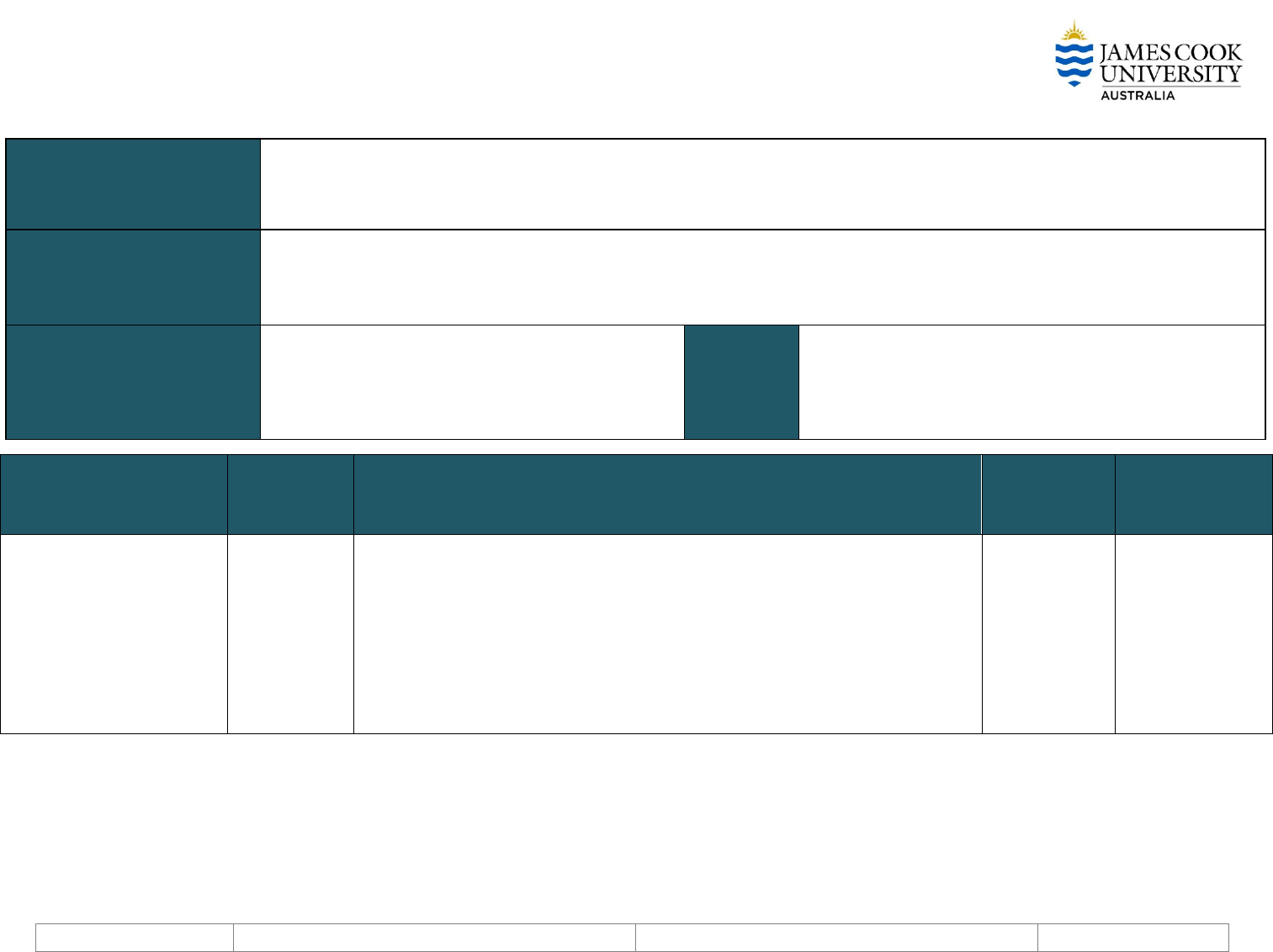

SECTION 4: RISK MATRIX

STEP 1 – Consequence Table

STEP 2 – Probability Table

Given that the event occurs, what is the likely outcome?

How likely is it that the event will occur?

Level

Incident

Level

CONSEQUENCE Level Likelihood PROBABILITY

1

Insignificant

No injury

1

Rare

The event may occur only in exceptional

circumstances

2

Minor

First Aid treatment

2

Unlikely

The event may occur at some stage

3

Moderate

Medical treatment required

3

Moderate

The event should occur at some stage

4

Serious

Extensive injuries

4

Likely

Event will probably occur in most circumstances

5

Disaster

Death

5

Almost Certain

Event expected to occur in most circumstances

STEP 3 – Risk Assessment Matrix

STEP 4 – RISK LEVEL

CONSEQUENCE This result to be inserted in WMS

PROBABILITY

1

Insignificant

2

Minor

3

Moderate

4

Serious

5

Disaster

High (18 – 25)

1 Rare

1

3

6

10

15

Significant (10 – 17)

2 Unlikely

2

5

9

14

19

Moderate (6 – 9)

3 Moderate

4

8

13

18

22

Low Risk (1 – 5)

4 Likely

7

12

17

21

24

5 Almost Certain

11

16

20

23

25

Apply Control Measures using Hierarchy of Control Measures:

1. Elimination; 2. Substitution; 3. Engineering / Isolation; 4. Administrative Controls; 5. Personal Protective Equipment

(PPE).

MOST EFFECTIVE LEAST EFFECTIVE

HSE-PRO-006a ASBESTOS MANAGEMENT – MINOR WORKS SWMS

Version: 1 Approval Date: Next Review Date: Page 21 of 21

SECTION 5: ACKNOWLEDGEMENT

All persons engaged in this work must read the SWMS and sign below.

By signing this safe work method statement I acknowledge that:

• I have read and understood the safe work method statement ; and

• I agree to follow the instructions and procedures listed in this safe work method statement.

Name

Signature

Date