Sustainability

Data

Book

2022

Sustainability Data Book

11

Sustainability Data Book Overview Overview of Toyota Motor Corporation

Promoting Sustainability Environment Social Governance Content Index

Overview

GRI

102-46, 48~52

1 Editorial Policy

2 Update History

3 Contents

Sustainability

Data Book

Overview

Updated in October 2022

The Sustainability Data Book explains Toyota’s sustainability approach and policies for

ESG initiatives along with practical cases and numerical data, as a medium for specialists

and those who are particularly interested in sustainability issues.

Since scal 2021, the Sustainability Data Book, which had conventionally been released

annually, has been updated whenever necessary so that the information can be disclosed

in a timely manner.

Period Covered

Focusing mainly on the results of initiatives implemented

during the previous scal year, the contents are updated as

necessary throughout the year. For update history, please see

the following page.

Scope of Report

This Book introduces the initiatives and activities of Toyota

Motor Corporation and its consolidated subsidiaries etc. in

Japan and overseas. The scope of data covered is described

in each section.

Toyota References in This Document

Toyota Motor Corporation:

Information on or initiatives of Toyota Motor

Corporation

Toyota: Information on or initiatives of Toyota Motor

Corporation and its consolidated subsidiaries

Reference Guidelines

�

Task Force on Climate-related Financial Disclosures

(TCFD)

�

Sustainability Accounting Standards Board

(Reference code

SASB

TR-AU-

is indicated at each

applicable part.)

P.113 SASB Content Index

�

GRI Standards

(Reference code

GRI

-

is indicated at each

applicable part.)

P.114 GRI Content Index

�

ISO 26000 Guidelines

Third Party Assurance

Third Party Assurance

denotes data assured by an Independent

Practitioner

Disclaimer

This report includes not only past and current facts pertaining

to Toyota Motor Corporation and other companies within the

scope of coverage of the report, but also plans and projections

at the time of its publication as well as forecasts based

on management policies and strategies. These forecasts

are assumptions or determinations based on information

available at the time they are stated, and the actual results

of future business activities and events may differ from the

forecasts due to changes in various conditions. In cases

where information provided in prior reports is corrected or

restated and in cases where material changes occur, the

details thereof will be indicated in this report. The readers’

understanding about this point would be appreciated.

Editorial Policy

|

Editorial Policy

|

Update History

|

Contents

|

Integrated Report

Securities Reports/SEC Filings

Financial Results/Operating Results

Sustainability Data Book

Corporate Governance Report

Non-nancial

Financial

IR section of Toyota’s website Sustainability section of Toyota’s website

Toyota Times website

Sustainability Data Book

22

Sustainability Data Book Overview Overview of Toyota Motor Corporation

Promoting Sustainability Environment Social Governance Content Index

Overview

|

Editorial Policy

|

Update History

|

Contents

|

December 2022 Promoting Sustainability Public Policy

October 2022 All pages updated (Review of FY2021 initiatives and layout)

August 2022 Environment Climate-related Financial Disclosures Based on TCFD

Recommendations

SASB/GRI Content Index

January 2022 Environment Strategy and Management, Environmental Data

December 2021 Promoting Sustainability Fundamental Approach, Public policy

Safety

Information Security and Privacy (The content transferred from “Governance” to “Society” and

expanded disclosure of more information about our contribution

to the society.)

Business Partners Dealers

Diversity and Inclusion Social Recognition

Intellectual Property (Newly added)

Risk Management Fundamental Approach

November 2021 Environment

October 2021 Quality and Customer

Social Contribution Activities

Respect for Human Rights

Business Partners Supply Chain

Diversity and Inclusion

Social Data

Risk Management Business Continuity Management (BCM)

Compliance Bribery / Corruption Prevention Measures

July 2021 Overview of Toyota Motor Corporation

Promoting Sustainability Organizational Structure

Quality and Customer Quality

Respect for Human Rights

Health and Safety

Diversity and Inclusion

Human Resources

Social Data

Corporate Governance

Risk Management Initiatives for Information Security

Compliance

Update History

Sustainability Data Book

33

Sustainability Data Book Overview Overview of Toyota Motor Corporation

Promoting Sustainability Environment Social Governance Content Index

Overview

|

Editorial Policy

|

Update History

|

Contents

|

Overview

Sustainability Data Book Overview Editorial Policy 1

Update History 2

Contents 3

Overview of Toyota Motor Corporation Company Prole 5

Promoting Sustainability Fundamental Approach 6

Organizational Structure 6

Materiality (key issues) 7

Toyota’s SDGs 7

Stakeholder Engagement 8

Public Policy 9

Environment

Policy and Environmental Management Fundamental Approach 11

Environmental Management 11

Initiatives with Suppliers 13

Initiatives with Dealers and Distributors 15

Stakeholder Engagement 16

Climate Change Fundamental Approach 17

Life Cycle 18

Product 22

Production 25

Resource Recycling Fundamental Approach 28

Activities to Achieve Resource Recycling 28

Harmony with Nature Fundamental Approach 31

Biodiversity 31

Water Environment 35

Climate-related Financial Disclosures Based on TCFD Recommendations

Governance 37

Strategy 38

Risk Management 42

Metrics and Targets 43

Environmental Data Greenhouse Gases (GHG) 46

Energy 47

Water 48

Recycling 49

Waste 50

VOC, NOx, SOx 50

Conversion Factors 50

FY2022 Review of the 7th Toyota Environmental Action Plan (2025 Target) 51

Third-party Verication 54

Social

Respect for Human Rights Fundamental Approach 57

Organizational Structure 57

Policy development and dissemination 58

Human Rights Due Diligence 58

Initiatives for Migrant labor (forced labor) 59

Initiatives for Wage 60

Initiatives for Working Hours 60

Initiatives for Flexible Work Styles 60

Initiatives for Anti-harassment 60

Initiatives for Child Labor 61

Initiatives for Freedom of Association 61

Initiatives for Precarious Work 61

Responsible Mineral Procurement 62

Education related to Human Rights 62

Diversity and Inclusion Fundamental Approach 63

Organizational Structure 63

Women's Activity 64

Nursing Care Support 67

Inclusion of Persons with Disabilities 68

Inclusion of LGBTQ+ employees 69

Initiatives Related to Race and Nationality

promotion 70

Employment for Over 60s 70

Value Chain Collaboration Fundamental Approach 71

Initiative with Suppliers 71

Initiative with Dealers 73

Vehicle Safety Fundamental Approach 74

Integrated Safety Management Concept 74

Active Safety 75

Passive Safety 76

Emergency Response 76

Automated Driving Technology 77

Initiatives to Improve Trafc Safety Awareness 77

Quality and Service Fundamental Approach 78

Organizational Structure 78

Product Safety Initiatives 79

Quality Risk Management 79

Fostering Quality-oriented Awareness and

Culture 79

Coping with Quality Problems 80

Contents

Sustainability Data Book

44

Sustainability Data Book Overview Overview of Toyota Motor Corporation

Promoting Sustainability Environment Social Governance Content Index

Overview

|

Editorial Policy

|

Update History

|

Contents

|

After-sales Service 80

Customer Feedback System 81

Information Security Fundamental Approach 82

Organizational Structure 82

Information Security Measures 83

Preparing for Information Leaks and External

Attacks 83

Security for Automobiles 84

Privacy Fundamental Approach 85

Organizational Structure 85

Respect for Privacy and Protection of Personal

Information 86

Intellectual Property Fundamental Approach 87

Organizational Structure 87

Intellectual Property Activities 87

Human Resource Development Fundamental Approach 88

Recruitment 88

Education and Career Development 89

Evaluation of and Feedback to Employees 91

Employee Satisfaction Survey 91

Health and Safety Fundamental Approach 92

Organizational Structure 93

Health and Safety Education 93

Initiative for Health 94

Initiative for Safety 95

Social Contribution Fundamental Approach 97

Organizational Structure 97

Social Contribution Activities 97

Social Data Employees 98

Supply Chain 99

Quality 99

Social Contribution Activities 99

Governance

Corporate Governance Fundamental Approach 101

Corporate Governance Structure 101

Board of Directors 102

Audit & Supervisory Board 103

Executive Compensation 103

Internal Control 103

Risk Management Fundamental Approach 104

Organizational Structure 104

Risk Management System 105

Business Continuity Management (BCM) 105

Compliance Fundamental Approach 108

Compliance Education 108

Bribery / Corruption Prevention Measures 109

Initiatives for Taxation 109

Speak-up 109

Checks to Enhance Compliance 110

Governance Data Governance 111

SASB/GRI Content Index

SASB Content Index 113

GRI Content Index 114

Sustainability Data Book

55

GRI

102-1~7, 16

5 Company Profile

Overview of

Toyota Motor

Corporation

Updated in October 2022

No. of plants and manufacturing companies (as of the end of March, 2022)

No. of R&D centers (as of the end of March, 2022)

Europe

7

3

Other

7

0

Japan

16

8

North America

13

5

Asia

26

4

Excluding Japan

No. of

Employees

372,817

(as of the end of

March, 2022)

Asia

66,328

Europe

24,852

Japan

203,948

Other

22,218

North America

55,471

No. of vehicles

produced

8,158,223

(FY 2022)

Asia

1,498,557

Japan

3,738,321

Other

462,698

North America

1,751,915

Europe

706,732

No. of

vehicles sold

8,230,425

(FY 2022)

Asia

1,542,918

Japan

1,924,185

Other

1,352,311

Europe

1,017,099

North America

2,393,912

No. of plants and manufacturing companies (as of the end of March, 2022)

No. of R&D centers (as of the end of March, 2022)

Europe

7

3

Other

7

0

Japan

16

8

North America

13

5

Asia

26

4

Excluding Japan

No. of

Employees

372,817

(as of the end of

March, 2022)

Asia

66,328

Europe

24,852

Japan

203,948

Other

22,218

North America

55,471

No. of vehicles

produced

8,158,223

(FY 2022)

Asia

1,498,557

Japan

3,738,321

Other

462,698

North America

1,751,915

Europe

706,732

No. of

vehicles sold

8,230,425

(FY 2022)

Asia

1,542,918

Japan

1,924,185

Other

1,352,311

Europe

1,017,099

North America

2,393,912

Financial Data

For our major nancial data, please see our of cial website.

Financial Data

SASB

TR-AU-000.A

SASB

TR-AU-000.B

Sustainability Data Book Overview Overview of Toyota Motor Corporation

Promoting Sustainability Environment Social Governance Content Index

Overview

Company Name Toyota Motor Corporation

President and

Representative

Director

Akio Toyoda

Company Address

Head Of ce

Tokyo Head Of ce

Nagoya Of ce

1 Toyota-cho, Toyota City, Aichi Prefecture, Japan

1-4-18 Koraku, Bunkyo-ku, Tokyo, Japan

4-7-1 Meieki, Nakamura-ku, Nagoya City, Aichi

Prefecture, Japan

Founded August 28, 1937

Capital 635.4 billion yen (as of the end of March, 2022)

Main Business

Activities

�

Automotive business

�

Financial services (vehicle loans and leasing, etc.)

�

Other operations (information technology, etc.)

No. of Employees

(consolidated)

372,817 (as of the end of March, 2022)

No. of Consolidated

Subsidiaries

559 (as of the end of March, 2022)

No. of Associates

and Joint Ventures

Accounted for by

the Equity Method

169 (as of the end of March, 2022)

Vision & Philosophy

For details of our Vision & Philosophy, please see our of cial

website.

Vision & Philosophy

Company Profile

Global/Regional Data

|

Company Profile

|

Sustainability Data Book

66

Organizational Structure

Aim

•

Addressing issues of greater importance and urgency on a priority basis while grasping,

for example, changes in the external environment and social needs.

Initiative

•

In 2019: Set up the Sustainability Management

Department.

•

Continuously promoting and improving our

sustainability activities, such as environmental,

social, and governance initiatives, while

working in close liaison with relevant

departments.

•

In 2020: Appointed a Chief Sustainability

Of cer (CSO) as the leader of the promotion of

sustainability activities.

Sustainability Meeting Sustainability Subcommittee

Chairperson Chairperson of the Board of Directors CSO

Member Members of the Board of Directors Operating of cers responsible, etc.

Frequency Twice a year, in principle Six times a year, in principle

Function

•

To supervise and make decisions on

identifying key sustainability issues, its

countermeasures and the promotion of

the activities

•

To execute operations related to the

promotion of sustainability

•

To report important issues to the

Sustainability Meeting

Fundamental Approach

Aim

•

Contributing to the creation of a prosperous society through our business activities based

on the Guiding Principles at Toyota while continuing to uphold the spirit of the Toyoda

Principles, which we have inherited since our foundation.

•

Aiming to be the "best company in town" that is both loved and trusted by local people

to achieve the mission of "Producing Happiness for All" under the Toyota Philosophy

compiled in 2020.

⇒ Contributing to the sustainable development of our society and planet by

promoting sustainability under the Toyota Philosophy.

Toyota Philosophy

Guiding Principles at Toyota

Initiative

•

Advancing initiatives based on our Sustainability Fundamental Policy and individual

policies and guidelines.

Sustainability-related policies

Sustainability Fundamental Policy

<Related policies>

Environment Earth Charter Policy on Harmony with Nature

Information Information Security Policy Toyota Privacy Notice

Human rights Human Rights Policy

Supply chain

Basic Purchasing Policies

Policies and Approaches to

Responsible Mineral Sourcing

Green Purchasing Guidelines

Supplier Sustainability Guidelines

Policy for Sustainable Natural Rubber

Procurement

Health and safety

Declaration of Health

Commitment

Basic Philosophy for Safety and Health

Social contribution

Basic Principles and Policies of

Social Contribution Activities

Compliance Toyota Code of Conduct Anti-Bribery Guidelines

Taxation Tax Policy

6 Fundamental Approach

6 Organizational Structure

7 Materiality (key issues)

7 Toyota’s SDGs

8 Stakeholder Engagement

9 Public Policy

Promoting

Sustainability

Updated in December 2022

GRI

102-12, 13, 18~21, 26, 27, 29, 32, 40, 42~44, 103-1~3

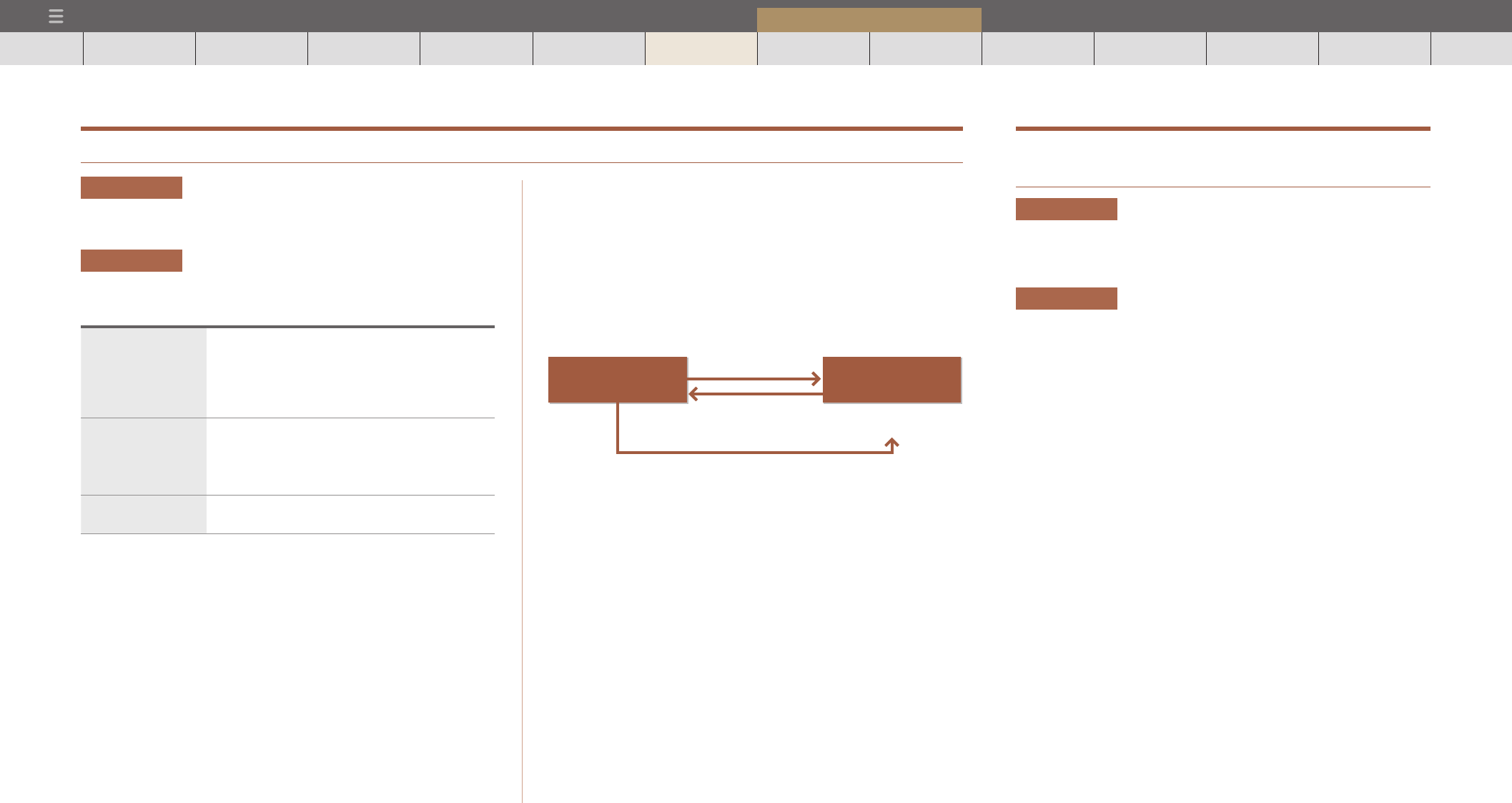

[Management Oversight and

Decision-Making]

[Operational Execution]

Supervise Submit/Report

Board of Directors

Sustainability Meeting

Operating Ofcers

Sustainability Subcommittee

Overview Environment Social Governance Content Index

Promoting Sustainability

|

Fundamental Approach

|

Organizational Structure

|

Materiality (key issues)

|

Toyota’s SDGs

|

Stakeholder Engagement

|

Public Policy

|

Sustainability Data Book

77

Aim

Identifying key issues to sustainably enhance our own corporate value while contributing to society in view of the ever-changing social trends, external voices, and

increasingly diversi ed, complicated issues.

Initiative

•

Promoting initiatives to realize the six key issues (materiality).

Materiality (key issues) Toyota’s SDGs

Aim

•

Producing happiness for all individuals in the era of diversi cation, with a

“YOU perspective” that sees the other side of the story.

Initiative

•

Promoting initiatives based on the desire of working for the bene t of others,

which has been passed on since our founding.

Examples

•

Initiatives for the global environment

•

Initiatives for a happier society

•

Initiatives for working people

SDGs Initiatives

Listing issues

●

Major references

• International guidelines, norms (GRI, SASB,

SDGs, etc.)

• Priority items of evaluation organizations

• Trends inside and outside Japan

• Risk and opportunity perspective

Evaluation from internal

and external viewpoints

●External

• Priority items for investors or evaluation

organizations

• Opinions obtained through communication

with stakeholders

●Internal

• Factors we have cultivated so far (founding spirit)

• Anticipated environmental changes

(transformation into a mobility company)

Evaluation from social

viewpoints

• Value that Toyota can offer society

• Contribution to solving social issues (SDGs)

Discussion

• Discussion at Sustainability Meeting attended

by Outside Directors and Audit and

Supervisory Board Members

Enhancing corporate value

Contributing to society (SDGs)

●

Respect for people, empower various human resources

●

Make safe, reasonably priced, high-quality cars

●

Maintain a stable business base

●

Build a future mobility society

●

Address climate change and promote the use of new energy sources

●

Make the value chain resilient and sustainable

Process of

identification

Basis for

identification

Six materiality issues

Transformation into a mobility company

Factors that we should change or reinforce

●

Business (nancial): Adapt to CASE*

●

Non-nancial: Commit to ESG

Founding spirit

Factors that we should continue to maintain

●

Principle: Five Main Principles of Toyoda

●

Strengths: Capabilities and technologies of monozukuri (manufacturing),

Toyota Production System, cost reduction, quality, many partners, etc.

* CASE: Connected, Autonomous/Automated, Shared, and Electric

Overview Environment Social Governance Content Index

Promoting Sustainability

|

Fundamental Approach

|

Organizational Structure

|

Materiality (key issues)

|

Toyota’s SDGs

|

Stakeholder Engagement

|

Public Policy

|

Sustainability Data Book

88

Aim

•

Engaging in stakeholder-oriented management to contribute to sustainable

development and striving to maintain and develop sound relationships

with stakeholders through open and fair communication.

Initiative

•

Holding dialogues with major stakeholders through Toyota’s relevant divisions and of ces around the world.

•

Disseminating information about Toyota’s initiatives through dialogues with external experts to examine, for example, the direction of our sustainability-related initiatives,

and through speech delivery at external lecture meetings.

Stakeholder Engagement

Communication methods and frequency

Incorporation into corporate activities

Customers

●Toyota Customer Assistance Center (as needed)

Responding to customer opinions by telephone and email forms

Improving customer satisfaction

activities

●Ofcial website, product websites (as needed)

Disseminating company information and business details,

providing FAQs, etc.

●Information sharing through social media (as needed)

Disseminating company information and business details

Disseminating information in

response to customer demand

Communication methods and frequency

Incorporation into corporate activities

Employees

●Joint labor-management roundtable conferences/

Labor-management meetings (several times a year)

Discussions/negotiations, opinion exchanges and mutual

understanding regarding labor-management issues

Strengthening labor-management

relationships

●

Employee satisfaction survey (once or twice every two years)

Surveying employees’ satisfaction regarding workplace culture and company life

Communication methods and frequency

Incorporation into corporate activities

Business Partners

[Dealers]

●Various meetings, seminars, and events

(as needed)

Sharing corporate policies

Building closer, mutually

benecial relationships based

on mutual trust

Sharing purchasing policies and strengthening

mutual study and partnerships

Communication methods and frequency

Incorporation into corporate activities

Shareholders

●Shareholders’ Meeting (once a year)

Unconsolidated and consolidated nancial statements, audit and

supervisory board reports, and deliberation and decisions on resolutions

●Financial results announcement (four times a year)

Press and telephone conferences to explain Toyota’s nancial status

and initiatives

●Individual meetings (as needed)

Explanation and discussion on nancial status, local projects,

technologies, products, etc. with institutional and private investors

Improving management quality

through constructive dialogue

●Investor information website, etc. (as needed)

Providing information on nancial status, business details, etc.

Communication methods and frequency

Incorporation into corporate activities

Local Communities/

Global Society

●Roundtable conferences with local residents

(several times a year)

Explanation and discussions with local representatives on

Toyota’s initiatives at each plant

●Inviting local communities to Toyota’s events and

participating in local events (as needed)

Social gatherings with local residents

●Participating in joint projects between public and private

sectors (as needed)

Cooperating in progressive initiatives such as verication tests

●Participating in economic and industry organizations

(as needed)

●Participating in collaborative activities with NGOs and

NPOs (as needed)

Social contribution activities in each region around the world

Recognizing social needs

in individual regions

Toyota

Based on our “Customer First” policy, we take measures to

incorporate the comments and opinions of customers into better

products and services.

Timely and appropriate disclosure of operation and nancial results

to shareholders and investors, and constructive dialogues toward

sustained growth and enhancement of corporate value.

Bilateral communications to build teamwork and foster a sense of unity

based on a labor-management relationship founded on mutual trust

and responsibility.

Close communication to achieve a mutually benecial

relationship based on mutual trust.

[Suppliers]

●Supplier conventions, various meetings with

supplier associations, seminars, and events

(as needed)

Dialogue with various stakeholders to build good

relationships with local communities and to solve global

social and environmental issues.

Improving workplace culture and

evaluating and planning various labor-

management and personnel policies

Promoting mutual

understanding and forming

stable local communities

Improving advanced

technologies and recognizing/

resolving social issues

Introducing policies to improve

the vitality of the nation/

industries

•

Major initiative we participate in

•

World Business Council for Sustainable Development (WBCSD)

P.16 Stakeholder Engagement (Environment)

P.58 Engagement with stakeholders (Human Right)

Overview Environment Social Governance Content Index

Promoting Sustainability

|

Fundamental Approach

|

Organizational Structure

|

Materiality (key issues)

|

Toyota’s SDGs

|

Stakeholder Engagement

|

Public Policy

|

Sustainability Data Book

99

Public Policy

Aim

•

Carrying out Toyota’s mission “Producing Happiness for All” and aiming

to be the No. 1 company in the community, loved and relied on by local

residents.

•

For example, in terms of climate change, it is very important to expand

the use of electric vehicles worldwide. In the process of achieving this

objective, governments and the authorities concerned have a crucial role

in developing energy policies and infrastructure. Working and learning

together with stakeholders, Toyota will maximize its contribution to local

communities and the development of public policies in consideration of

policies, social needs, technological advancement, and various customer

needs while always bearing transparency and compliance in mind.

Initiative

•

Building good relationships with governments and their administrative

agencies, regulators, political parties, NGO, local communities, customers,

and other stakeholders.

•

Participating in economic organizations and industry associations around the

world and many ofcers and employees are involved in and contribute to

formulating policy recommendations.

•

Disclosing Toyota’s Views on Climate Public Policies

•

Being more transparent about our activities, building and increasing

trust with the public, and further strengthening cooperation between all

stakeholders by summarizing our views on key climate-related policies and

providing an overview of the industry associations to which we belong.

2022

Overview Environment Social Governance Content Index

Promoting Sustainability

|

Fundamental Approach

|

Organizational Structure

|

Materiality (key issues)

|

Toyota’s SDGs

|

Stakeholder Engagement

|

Public Policy

|

Sustainability Data Book

1010

11 Policy and Environmental Management

17 Climate Change

28 Resource Recycling

31 Harmony with Nature

37 Climate-related Financial Disclosures Based on TCFD Recommendations

46 Environmental Data

51 FY2022 Review of the 7th Toyota Environmental Action Plan (2025 Target)

54 Third-party Veri cation

Environment

Overview Promoting Sustainability Social Governance Content Index

Environment

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

Sustainability Data Book

1111

SDGs

Contri-

butions

GRI

102-16, 102-29, 103-2, 103-3,

305-6, 306-2, 307-1, 308-1, 308-2

11 Fundamental Approach

11 Environmental Management

13 Initiatives with Suppliers

15 Initiatives with Dealers and Distributors

16 Stakeholder Engagement

Policy and

Environmental

Management

Updated in October 2022

Aim

•

To achieve sustainable development together with society, establish the environmental

management system with consolidated subsidiaries to ensure through risk management

and compliance and maximize environmental performance.

•

Always improve the management system and quickly respond to changes in environmental

issues including worsening climate change.

Initiative

Establish an Environmental Management System

•

Establish strategies, policies and approaches in each eld under the lead of the three

committees of the Environmental Product Design Assessment Committee, the Production

Environment Committee, and the Resource Recycling Committee, under the supervision

of the Board of Directors.

•

Share our target with the following companies and proceed with environmental management

•

Consolidated subsidiaries on a nancial accounting basis (493 companies).

•

Unconsolidated vehicle production companies (9 companies).

•

Set environmental affairs of ces in the six regions (North America, Europe, China, Asia,

South America, and South Africa) and proceed with global environmental efforts with

consideration given to local conditions.

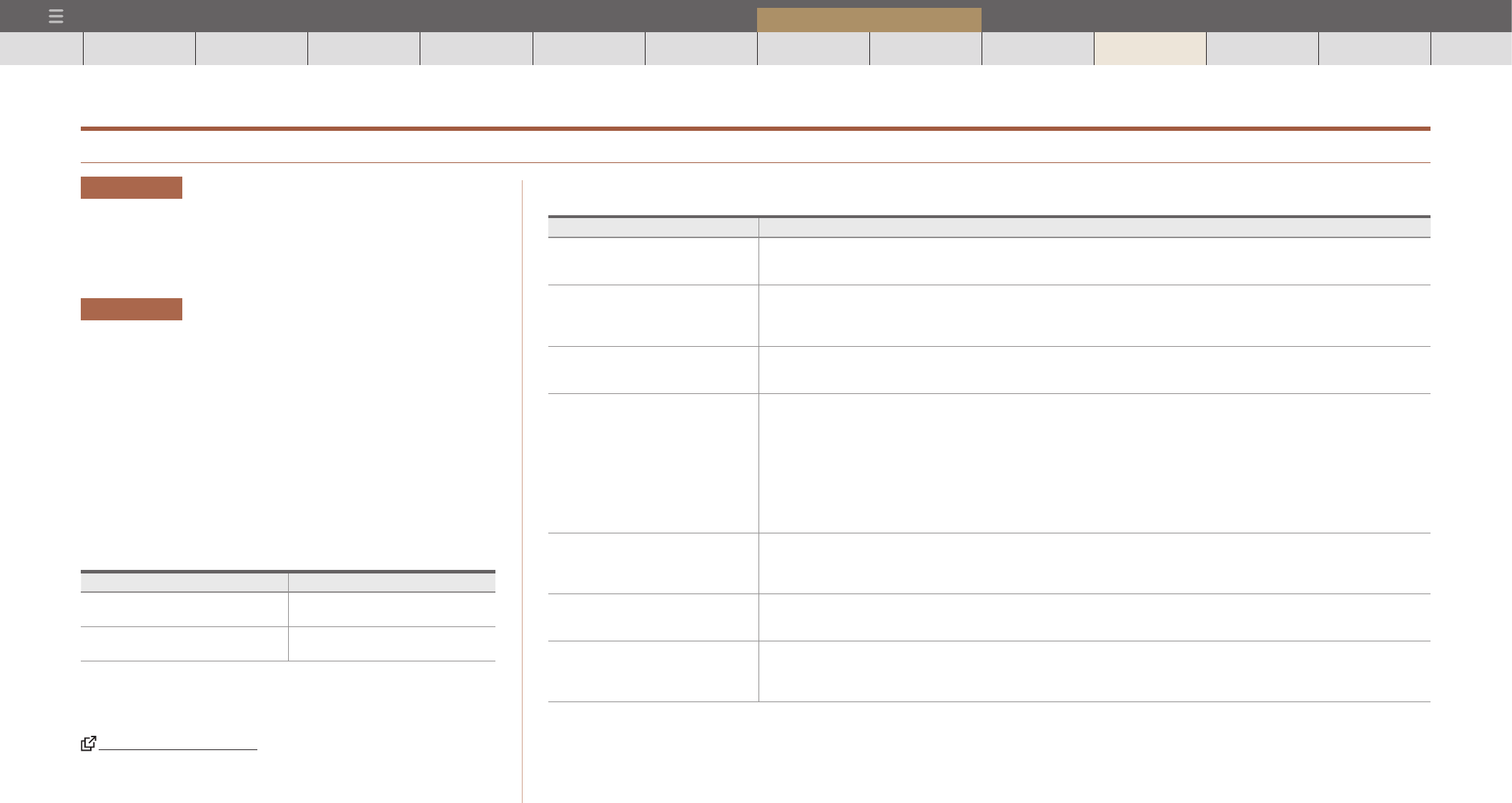

Global Environmental Management Framework

Toyota Motor Corporation Region

Strategy/target

Implementation

Regional 2025 Target

Share

Cooperate

E.g., various global

committees

Toyota Environmental Challenge

2050

Global 2025 Target

Environmental Product Design

Assessment Committee,

Production Environment Committee,

Resource Recycling Committee,

etc.

E.g., Regional Environmental

Committee

North America, Europe, China, Asia,

South America, and South Africa

Environmental Management

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

Overview Promoting Sustainability Social Governance Content Index

Environment

Fundamental Approach

Aim

•

Reduce the environmental footprint and contribute to the sustainable development of

society and the world throughout all areas of our business activities.

•

Build close, cooperative relationships with a wide spectrum of individuals and organizations

involved in environmental preservation.

Initiative

Toyota Earth Charter

•

Conducting continuous environmental initiatives since the 1960s.

•

Established the Toyota Earth Charter in 1992 (revised in 2000).

•

Formulated our long-term initiatives for the global environment by 2050 as the Toyota

Environmental Challenge 2050, in 2015.* Subsequently advancing various initiatives

centered on this.

* 2015: The 21st session of the Conference of the Parties to the United Nations Framework Convention on Climate Change (COP21)

was held this year.

Vision & Philosophy

Toyota Earth Charter

P.44 Toyota Environmental Challenge 2050

|

Fundamental Approach

|

Environmental Management

|

Initiatives with Suppliers

|

Initiatives with Dealers and Distributors

|

Stakeholder Engagement

|

Sustainability Data Book

1212

Major Targets and Progress (excluding the initiatives to address climate change, recycle

resources, and ensure harmony with nature)

2025 Target 2021 Initiatives

Chemical

substances

•

Implement thorough management by carefully

considering legal trends in each country and region

•

Steadily introduced vehicles that satisfy the latest legal

requirements and substance regulations

•

Continued to evaluate and improve chemical substance

management structures by auditing and investigating

suppliers’ processes in various regions on a global basis

Air quality

•

Product:

•

Steadily introduce low-emission vehicles and boost

further improvement by introducing and increasing

ZEVs*

•

Production:

•

Continue volatile organic compound (VOC) emission

reduction activities and maintain industry-leading level

* Zero Emission Vehicles: Vehicles that have the potential not to emit any

CO

2

or nitrogen oxide (NOx) during driving, such as battery electric vehi-

cles (BEVs) and fuel cell electric vehicles (FCEVs)

•

Product:

•

In response to stricter emission regulations in various

countries and regions, introduced vehicles that satisfy

those regulations

•

Production:

•

Promoted a switch to water-based paint in the bumper

painting process

•

Took measures to completely eliminate the use of

ozone-depleting substances (ODS)

•

No signicant releases occurred

P.50 Environmental Data [T]

Waste

•

Promote activities to thoroughly reduce waste globally

and aim to minimize the volume of resource input and

waste, with the environment and economy in balance

•

Promoted waste reduction and efcient use of resources

through measures aimed at the sources of waste

P.50 Environmental Data [R]

•

Production:

•

Maintain the volume of waste per vehicle produced at

each plant below 2018 levels

•

Production:

•

Took measures aimed at the sources of waste,

developed and deployed production technologies, and

implemented daily reduction activities

•

Hazardous waste management: Ensured that end-of-

life vehicle treatment was in compliance with the laws

and regulations of each country at every plant

•

Did not import or export any hazardous waste listed in

Annexes I, II, III or VII of the Basel Convention

Logistics

packaging

•

Implement initiatives to reduce and recycle plastics used

in packaging and recycle them

•

Promoted kaizen with a focus on increasing use of

returnable containers and reducing the weight of packaging

P.50 Environmental Data [S]

Risk

management

•

Thoroughly comply with environmental laws and

regulations and strengthen proactive prevention activities

for environmental risks in each country and region

•

Two non-compliance issues (one concerning abnormal

water quality and one concerning exhaust gas) in the

production area ⇒ Completed measures for the cases

•

One complaint (concerning noise) in a non-production

area ⇒ Completed measures for the case

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

Overview Promoting Sustainability Social Governance Content Index

Environment

ISO

*1

14001/ISO 50001

Certication as of 2021

•

ISO 14001: All plants of Toyota Motor Corporation and consolidated subsidiaries (122 companies)

•

ISO 50001: 8 of the above companies

*1 International Organization for Standardization

Risk Management and Compliance

•

Take the following actions at the operating bases of Toyota Motor Corporation and consolidated subsidiaries:

•

Implement preventive measures

•

Undertake risk management in accordance with criteria that meet or exceed laws and regulations

•

Have systems in place, just in case, to respond to a violation or a complaint in a timely manner, and if such

a situation occurs, work to prevent reoccurrence through identication of root causes

•

Conduct mutual learning for plants by sharing practices among Toyota Group companies

Maximize Performance

•

Proceed with initiatives to address climate change, resource recycling, and harmony with nature based on the

Toyota Environmental Challenge 2050.

P.13 Initiatives with Suppliers

P.17 Climate Change

P.28 Resource Recycling

P.31 Harmony with Nature

•

For chemical substances, air quality, and other compliance-related initiatives, and also for waste and logistics

packaging, proceed with initiatives based on the 2025 target.

Outside Evaluation for Our Commitment to Climate Change and Water Security

CDP*2 Corporate Research

•

Selected for inclusion in the A List, which is the highest evaluation for climate change and water security by

the CDP (in December 2021).

*2 An international NGO that encourages and assesses corporate disclosures on environmental initiative based on calls from global institutional investors with

high levels of interest in environmental issues

|

Fundamental Approach

|

Environmental Management

|

Initiatives with Suppliers

|

Initiatives with Dealers and Distributors

|

Stakeholder Engagement

|

Sustainability Data Book

1313

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

Overview Promoting Sustainability Social Governance Content Index

Environment

Initiatives with Suppliers

Aim

•

Work together with suppliers toward reducing the environmental footprint

throughout the product life cycle based on the concepts of mutual trust

and mutual benet, thereby contributing to accomplishing a sustainable

society.

Initiative

Green Purchasing* Policy

Implementation of the Green Purchasing Guidelines

•

Ask all tier 1 suppliers, including new suppliers, to implement basic initiatives

based on the TOYOTA Green Purchasing Guidelines (the “guidelines”), and

also deploy and enlighten the guidelines to all tier 2 and subsequent suppliers

so that the guidelines will take root.

•

Ask through the guidelines that initiatives be taken toward reducing the

environmental footprint at each company’s production plants and throughout

the product life cycle, and that related legal compliance be ensured.

* Prioritizing the purchase of parts, materials, equipment and services with a low environmental footprint when

manufacturing products

•

Overseas Practices related to the Green Purchasing Policy

•

Ask the purchasing base in each region to implement the guidelines in line

with local conditions and make continuous efforts.

Cases

Toyota Motor North America (North America)

•

Updated the existing guidelines and issued the Green Supplier Requirements

in April 2021, and reinforced environmental management by including

compliance with requirements (CO

2

emission reductions) in the terms and

conditions.

Green Purchasing Guidelines

Supplier Sustainability Guidelines

Compliance with the Guidelines

•

Referred to the possibility that if we do not observe improvement after the

occurrence of a supplier’s violation of the guidelines, such as non-compliance

with laws and regulations, the transactional relationship may be subject to

review.

•

Already informed tier 1 suppliers of these points by including them in the

Supplier Sustainability Guidelines (revised in 2021).

Supplier Sustainability Guidelines

Monitoring

Self-assessment Sheet

•

Use a self-assessment sheet to conrm the status of initiatives by each

company and share the results.

FY2022 Results

•

Received responses from 227 main companies in Japan and provided

feedback on the scoring results.

CDP Supply Chain Program

•

Introduced the CDP Supply Chain Program in 2015 to support continuous

environmental initiatives conducted with suppliers, enabling us to determine

the supplier’s risks, opportunities and initiatives on climate change and water

security.

•

Create opportunities for environmental communication by annually holding

brieng sessions and response guidance where we share information on

social trends and Toyota’s environmental policies, and provide feedback on

response results, with the number of participating suppliers increasing every

year.

2021 Results

•

Received responses from suppliers accounting for approximately 83

percent of the total purchasing value by Toyota Motor Corporation.

•

Approximately 54 percent of these suppliers reduced their CO

2

intensity

(per unit of net revenue) compared to the previous year. (Affected by the

sluggish production due to the COVID-19 pandemic, the uctuation rate

was greater than that of the previous year.)

Main Results of the CDP Supply Chain Program (2021)

Climate Change

Water Security

Number of responding companies 133 118

Response rate 98 95

Percentage

responding

“Yes”

Governance (board-level

oversight, corporate policy)

95 76

Identifying risks 89 68

Integrating issues into business

strategy

94 75

Setting quantitative targets

94 70

|

Fundamental Approach

|

Environmental Management

|

Initiatives with Suppliers

|

Initiatives with Dealers and Distributors

|

Stakeholder Engagement

|

Sustainability Data Book

1414

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

Overview Promoting Sustainability Social Governance Content Index

Environment

|

Fundamental Approach

|

Environmental Management

|

Initiatives with Suppliers

|

Initiatives with Dealers and Distributors

|

Stakeholder Engagement

|

Initiatives toward Reducing CO

2

Emissions

•

Towards carbon neutrality throughout the product life cycle, started to

investigate concrete CO

2

reduction measures by presenting CO

2

reduction

guidelines tailored to each supplier.

2025 Target

•

Work with major suppliers in each country and region toward reducing CO

2

emissions.

•

Regions in scope: Regional head ofces with a purchasing function (in

Japan, North America, Europe, China, Asia, South America and South

Africa)

2021 Results

•

Steadily accomplished the target set in each country or region.

Risk Management

Ensuring Compliance with Regulation Concerning REACH

*1

and Other

Global Regulations on Chemical Substances

•

Comply with laws and regulations on chemical substances in various

countries and regions, such as the Chemical Substances Control Law

*2

in

Japan, and the Directive on ELV

*3

and Regulation concerning REACH of the

European Union (EU).

•

Improve structures and undertake operational management in cooperation

with all parties involved in conveying chemical substance information.

•

Continue industry collaboration and global deployment and comprehensive

implementation of action standards tailored to the cultures and industrial

structures of each region.

FY2022 Results

•

Revised regulations based on the Global Automotive Declarable Substance

List (GADSL) to reect the latest laws and regulations in each country

(setting content rate targets for each substance in consideration of

regulatory requirements, etc.).

•

Steadily introduced vehicles that satisfy these regulations, and also began

to work in cooperation with European afliates to address data registration

regulations (WFD

*4

/SCIP

*5

) newly launched in Europe.

•

Conducted supplier awareness activities (361 companies) using self-

assessment check lists to ensure thorough management of chemical

substances, and continued to expand activities to other regions.

*1. Regulation concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals: A regulation

for managing chemical substances to protect human health and the environment

*2. Act on the Regulation of Manufacture and Evaluation of Chemical Substances: An act to prevent environmental

pollution caused by chemical substances that pose a risk of impairing human health and interfere with the

inhabitation and growth of ora and fauna

*3. Directive on End-of Life Vehicles: A directive designed to reduce the load of end-of-life vehicles on the

environment

*4. Waste Framework Directive: A waste framework directive in Europe

*5. Database of information on Substances of Concern in articles, as such or in complex objects [Products]

Environmental Due Diligence at the Time of Purchasing

•

Policies and Approaches to Responsible Mineral Sourcing

•

Established the Policies and Approaches to Responsible Mineral Sourcing

in accordance with the OECD guidance to take into account the impact

on local societies by the procurement of minerals that may cause social

problems regarding human rights and environment.

•

Due Diligence Policy

•

Identify and assess risks in the supply chain together with suppliers, and if

any risk is identied, implement appropriate measures that will lead to the

mitigation of the risk.

*6 OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conict-affected and High-risk

Areas

Policies and Approaches to Responsible Mineral Sourcing

P.62 Responsible Cobalt Procurement

P.30 Efforts toward Compliance with the New EU Battery Regulation

P.31 Challenge of Establishing a Future Society in Harmony with Nature

Supplier Hotline

•

Set up a supplier hotline in accordance with the Toyota Code of Conduct

and Toyota Basic Purchasing Policies, which call on suppliers to comply

with laws and regulations and to take fair and just actions, in order to allow

suppliers to report any action violating environmental laws, regulations, or

business manners that may have occurred in the supply chain, while assuring

anonymity.

Sustainability Data Book

1515

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

Overview Promoting Sustainability Social Governance Content Index

Environment

Initiatives through Supplier Briengs

•

Hold periodic supplier briengs where we share information on environmental

trends and Toyota’s environmental policies.

•

Organized an explanatory session in FY2022 for promoting activities to reduce

CO

2

emissions from items, and shared the goal of realizing carbon neutrality

by 2050, thereby accelerating our efforts toward the accomplishment.

P.72 Supplier Awareness Activities

Recognition of Supplier’s Environmental Initiatives

•

Annually present the Environmental Activity Awards, established in 2017 to

commend suppliers that conduct exceptional environmental initiatives.

|

Fundamental Approach

|

Environmental Management

|

Initiatives with Suppliers

|

Initiatives with Dealers and Distributors

|

Stakeholder Engagement

|

Initiatives with Dealers and Distributors

Aim

•

Work together with dealers and distributers toward reducing the

environmental footprint, help them earn trust from their local communities

and serve as the “Best-in-Town”, and contribute to the communities and

customers.

Initiative

Implement the Environmental Global Policy in the Sales

and Service Area

•

Continuing to implement a strategy to reduce the environmental footprint in

store operations since 2016.

Regions

•

Dealers in 54 major countries and regions, such as Japan, North America,

Europe, Asia, Latin America, Oceania, and Africa (approximately 13,000

stores, accounting for 92 percent of the total in terms of the number of

vehicles sold).

Actions

•

Establish a structure of environmental management system

•

Minimize environmental risks

•

Improve environmental performance

•

Activities to make environment better with customers and society

Initiatives to Reduce CO

2

Emissions

2025 Target

•

100 percent introduction rate for CO

2

reduction items at newly constructed

and remodeled dealers.

2021 Results

•

Achieved the target in 41 countries and regions, and proceeding with

initiatives toward achieving the target in other countries and regions.

Awareness-raising Activities

Training for Purchasing Group Personnel

•

Provide group training for new employees regarding sustainability including

the environment.

•

Organize periodic study groups regarding carbon neutrality for staff who

communicate directly with suppliers.

Training Sessions with Suppliers

•

A variety of practical opportunities established by Toyota and its suppliers for

joint training on environmental issues.

Initiatives by Kyohokai*

•

Established research groups that consider environmental topics in 2019.

•

Organized working groups for four themes in 2021, and actively exchanged

information and held discussions for mutual learning by, for example, inviting

speakers from leading companies and holding on-site review meetings.

Issued a nal report to the entire Kyohokai in March 2022.

* Voluntary organization consisting of more than 200 suppliers delivering automotive components, bodies, etc.

to Toyota Motor Corporation

Study group with an invited expert

Sustainability Data Book

1616

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

Overview Promoting Sustainability Social Governance Content Index

Environment

Aim

•

Establish positive relationships with governments and their administrative

agencies, regulators, political parties, non-prot organizations, local

communities, customers, dealers, suppliers, and employees.

•

Contribute and commit to public policy by participating in activities by industry

and economic associations, and other initiatives.

Initiative

U.S. and Europe

•

U.S.: Participate in the Suppliers Partnership for the Environment

*1

and

promote environmental initiatives where suppliers, governments, NGOs and

other stakeholders collaborate.

•

Europe: Address key sustainability issues in the supply chain as a member

company of CSR Europe’s

*2

Drive Sustainability,

*3

an automobile industry

partnership program.

•

Participate in the WBCSD

*4

and apply what we learn through participation in a

trafc ow improvement verication program in Thailand, and other projects,

to our efforts to contribute to the realization of a sustainable society.

*1. A U.S.-based public-private partnership program for automobile manufacturers and suppliers to promote

sustainability

*2. A European NPO that operates a European business network to promote corporate sustainability

*3. A European partnership NPO that promotes sustainability in the automobile industry

*4. World Business Council for Sustainable Development: An NGO that conducts advocacy and verication

projects to realize a sustainable society with the participation of major corporations worldwide

Suppliers Partnership for the Environment

Drive Sustainability

World Business Council for Sustainable Development

Japan

•

Engage in public relations and present recommendations by ourselves or

through industry and economic associations regarding climate public policies,

such as those related to the Paris Agreement, the accomplishment of carbon

neutrality, and the stable supply of low-cost renewable energy.

•

Representative Afliation:

•

Japan Automobile Manufacturers Association, Inc. (JAMA)

•

Japan Business Federation (KEIDANREN)

Cases

JAMA

•

Reduce pollution, waste, or the use of resources.

•

Comply with the End-of-Life Vehicle Recycling Law: Collection, recycling

and appropriate treatment of CFC/HFC, airbags, and shredder residue

(ASR).

•

Proceed with the 3R efforts (reduction, reuse and recycling): Reduce

weight and make even better use of raw materials at the time of the design

of automobiles, and control the generation of designated byproducts or

recycle such items at the manufacturing phase.

•

Reduce in-car emissions of volatile organic compounds (VOCs).

•

Prohibit the use of the four heavy metals (lead, mercury, hexavalent

chromium, and cadmium) / public policy on considerable reduction.

Public Policy

Stakeholder Engagement

|

Fundamental Approach

|

Environmental Management

|

Initiatives with Suppliers

|

Initiatives with Dealers and Distributors

|

Stakeholder Engagement

|

Overseas Initiatives

Toyota Argentina S.A. (Argentina)

•

Ensured that all dealers in Argentina were ISO 14001 certied.

•

Launched the original environmental program “Eco Dealer Program” in 2018

with the involvement of all dealers.

•

Gave certication to dealers in three pharases according to their status

of environmental management framework, achievement levels of CO

2

reductions, etc.

•

Held a monthly meeting to share best practices, for example, for saving

energy and introducing renewable energy.

•

Reduced CO

2

emissions in FY2022 by 15 percent compared to 2018 levels

at the dealers in Argentina as a result of the above initiatives.

Sustainability Data Book

1717

Aim

•

Through contributing to achieving carbon neutrality,

aim to establish a sustainable society in harmony with

nature.

Initiative

•

As an initiative to tackle climate change under the

Toyota Environmental Challenge 2050, formulated “Life

Cycle Zero CO

2

Emissions Challenges,” “New Vehicle

Zero CO

2

Emissions Challenges,” and “Plant Zero CO

2

Emissions Challenges,” and started actions in 2015.

Fundamental Approach

SDGs

Contri-

butions

GRI

102-15, 103-1, 201-2, 302-4, 302-5, 305-3, 305-5

17 Fundamental Approach

18 Life Cycle

22 Product

25 Production

Climate

Change

Updated in October 2022

Equipment

manufacturers

Vehicle

manufacturing

Logistics

Driving

Recycling

Materials

and parts

manufacturing

PART

Parts

manufacturers

Materials

manufacturers

Other

companies

and industries

Logistics

companies

Energy

companies

Recycling

companies

Dealers and

distributors

Energy

companies

MATERIAL

renewable energy

Well to Wheel

*

renewable energy

* CO

2

emissions during driving as well as CO

2

emissions during the production stage of fuel and electricity (CO

2

emissions vary depending on the power supply con guration and

hydrogen production method, in the case of battery electric vehicles and fuel cell electric vehicles)

The bz4X, a new battery EV (BEV,) launched: with high power consumption ef ciency and practically suf cient cruising range ensured. Aimed at a world’s highest level of battery

capacity maintenance rate to develop a BEV that can be used for a long time with peace of mind.

Toyota is committed to reducing CO

2

emissions in each stage of the vehicle life cycle

Overview Promoting Sustainability Social Governance Content Index

Environment

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

|

Fundamental Approach

|

Life Cycle

|

Product

|

Production

|

Sustainability Data Book

1818

Aim

•

Achieve carbon neutrality by completely eliminate CO

2

emissions not only

during driving but throughout the entire vehicle life cycle including materials/

parts manufacturing, vehicle manufacturing, logistics, energy production,

disposal and recycling.

Initiative

•

Offer optimal products to minimize CO

2

emissions throughout the vehicle life

cycle by taking into consideration the energy situations and composition

ratios of power generation sources of each country/region.

•

Accelerate measures for the development of technologies that contribute to

CO

2

emissions reduction and create eco-friendly designs as we pursue “ever-

better cars”.

•

Step up efforts to reduce CO

2

emissions throughout the entire vehicle life

cycle while engaging in even closer communication with various stakeholders

in each stage of the value chain, including suppliers and dealers.

Zero CO

2

Emissions Throughout the Entire Vehicle Life Cycle in the Future

Zero CO

2

emissions

2013 2025 2030 Future vision

Reduce by 25% or more

Reduce by 18% or more

2021

Reduce by 13%

Life cycle CO

2

emissions

Life Cycle

Life Cycle Zero CO

2

Emissions Challenge

Completely Eliminate All CO

2

Emissions Throughout the Entire Vehicle Life Cycle

2025 Target 2021 Initiatives

Life cycle CO

2

emissions

•

Reduce CO

2

emissions* by 18 percent or more

throughout the entire vehicle life cycle compared to

2013 levels

* Per vehicle

•

Reduced CO

2

emissions* by 13 percent throughout the entire vehicle life cycle compared to 2013

levels

•

In 2021, four new models were assessed, and 45 of the total 61 (74 percent coverage) models

available for sale in 2021 in Japan was assessed by Eco Vehicle Assessment System (Eco-VAS).

Logistics

•

Japan:

Reduce CO

2

emissions by 7 percent by improving

transport efciency compared to 2018 levels (average

of 1 percent reduction per year)

•

Japan ⇔ Other regions:

Reduce CO

2

emissions by ocean-going vessels

(Switch two car carriers to liquid natural gas (LNG)

powered pure car carriers)

•

Ongoing kaizen activities

•

Loading efciency improvement

•

Joint transport

•

Modal shifts*

* Switching from cargo transport by car to means of transportation with less environmental impact, such as railway and ships

•

CO

2

emissions in Japan: 266,000 tons (down 8 percent compared to 2018 levels)

•

Introduced an LNG-powered vessel (total 3 vessels) to transport completed vehicles to North

America

Suppliers

•

Promote CO

2

emissions reduction activities among

major suppliers

•

Started and promoted communication with suppliers in each region on climate change measures

P.13 Suppliers (Environmental Management)

Dealers and

distributors

•

Newly constructed and remodeled dealers: achieve

100 percent introduction rate for CO

2

emissions

reduction items

•

Promoted initiatives to achieve the target in 54 major countries and regions, including Japan, North

America, Europe, Asia, Latin America, Oceania and Africa (which covers 92 percent of the total

vehicle sales)

•

Achieved the target in 41 countries and regions, and promoted initiatives to achieve the target in

other countries

P.15 Dealers (Environmental Management)

Overview Promoting Sustainability Social Governance Content Index

Environment

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

|

Fundamental Approach

|

Life Cycle

|

Product

|

Production

|

Sustainability Data Book

1919

Promoting Environmental Management in the Vehicle Life Cycle

•

Has been working to reduce CO

2

emissions by adopting LCA

*1

methods with

the aim of a clean car manufacturing throughout the vehicle life cycle.

•

Promoting the environmental management by using the Eco Vehicle

Assessment System (Eco-VAS), which was introduced in 2005, that sets

environmental targets during the vehicle development stage under the guidance

of the chief engineer and takes steady measures to achieve those targets.

•

Achieved life cycle CO

2

emission levels in all subject models equivalent to

or lower than those of reference vehicles (previous models or vehicles of the

same class).

e.g.,

• Reduced CO

2

emissions of the NX350h by 16 percent compared to

the previous model

*1 Life Cycle Assessment:

• A comprehensive assessment technique to quantify a vehicle’s impact on the environment (including global

warming, acidication and resource depletion) in each stage from resource extraction to disposal and recycling

• Toyota has acquired a certication based on the ISO 14040/14044 from TÜV Rheinland, a third-party

certication organization.

Eco-VAS Activity Cases:

LCA Results of CO

2

Reduction in the Vehicle Life Cycle for NX350h

Previous

model

Materials

manufacturing

Parts manufacturing

and vehicle assembly

Driving

Disposal and recycling

Maintenance

New

model

CO

2

index

16% reduction

0.0 0.2 0.4 0.6 0.8 1.0

Overview Promoting Sustainability Social Governance Content Index

Environment

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

|

Fundamental Approach

|

Life Cycle

|

Product

|

Production

|

Consideration in Each Stage of the Vehicle Life Cycle

•

Toyota has been working, in cooperation with its stakeholders, to achieve

carbon neutrality by 2050 by employing the Life Cycle Assessment (LCA)

methods to measure CO

2

emissions.

•

Carbon neutrality in LCA means to achieve carbon neutrality for not only

greenhouse gas (GHG) emissions during driving but all CO

2

generated

throughout the entire vehicle life cycle including materials, parts and vehicle

manufacturing, logistics, energy production, disposal and recycling.

Each Stage of the Vehicle Life Cycle

Disposal/

recycling

Energy

●

Renewable energy power

generation

●

Thermal power generation

Products

manufac-

turing

Vehicle

manufac-

turing

Well to Wheel

Materials

Tank to Wheel

vehicle driving

Fuel

manufacturing

Well to Tank

•

CO

2

emissions during driving are considered in two stages.

•

Well to Tank (WtT): From fuel extraction/production to a tank, or from power

generation to lling a battery

•

Tank to Wheel (TtW): From start of an engine or motor to driving wheels

•

While gasoline vehicles emit CO

2

during fuel production (WtT) and driving

(TtW), battery electric vehicles (BEVs) do not emit CO

2

during driving (TtW)

but if fossil fuel is used, CO

2

is generated during production of electricity (WtT)

and production of batteries.

•

To reduce CO

2

emissions of BEVs, conversion to renewable energy is crucial.

But the progress in conversion varies among countries and regions, making

it difcult to achieve complete conversion. It is therefore not easy to achieve

carbon neutrality only with BEVs. So, reduction of CO

2

emissions from the

existing powertrains, such as gasoline vehicles and hybrid vehicles, many of

which are present in market, should also be promoted by introducing low-

carbon synthetic fuels, such as biofuel and e-fuel.

P.23 Aiming at Carbon Neutrality through Product Development (Products)

Sustainability Data Book

2020

Cases of Initiatives in Energy Production and Usage

CO

2

-free hydrogen production and usage for Woven City and beyond

•

On March 23, 2022, ENEOS and Toyota announced to jointly explore CO

2

-

free hydrogen production and usage at Woven City, the prototype city

of the future that Toyota has started to develop in Susono City, Shizuoka

Prefecture, Japan.

•

The two companies have decided to commence construction and operation

of a hydrogen refueling station to produce and supply CO

2

-free hydrogen to

Woven City and Fuel Cell Electric Vehicles (FCEVs).

•

They are considering connecting the Community Energy Management

System (CEMS*) of Woven City with the hydrogen EMS to optimize hydrogen

production.

* Community Energy Management System

CO

2

-free hydrogen production and usage for Woven City and beyond

Developing a hydrogen-based new city of the future

•

On June 4, 2021, Fukushima Prefecture and Toyota announced that they

have commenced discussions with various partners over developing a city

for a new future that makes use of hydrogen and technologies produced

in Fukushima Prefecture.

•

Creating rst an implementation model for hydrogen-based deliveries at

supermarkets and convenience stores, which play a role both as essential

urban infrastructure and as evacuation areas in times of disaster, before

embarking on a challenge to apply the model to cities nationwide.

•

Making use of hydrogen produced at Fukushima Hydrogen Energy Research

Field (FH2R).

•

Introducing several fuel cell (FC) trucks for deliveries.

•

Optimizing operational management and hydrogen relling schedules through

the use of connected technologies, and carrying out energy management

that caters to the prevailing local conditions.

Building a hydrogen-based city of the future

Overview Promoting Sustainability Social Governance Content Index

Environment

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data

FY2022 Review of the 7th Toyota

Environmental Action Plan (2025 Target)

Third-party Verification

|

Fundamental Approach

|

Life Cycle

|

Product

|

Production

|

Considering from Energy Production Stage

Consideration to energy policies

•

In working toward achieving carbon neutrality, Toyota considers that various

elements affect energy policies of individual countries/regions as described

below:

•

Individual countries/regions are promoting various initiatives appropriate for

their energy situations, which vary among countries/regions depending on

their degree of development of social infrastructure and industry and the

presence of resources.

•

Meanwhile, recent tight power supply and soaring energy prices are

affecting energy policies of countries.

Consideration to characteristics of each power generation method

•

In working toward achieving carbon neutrality, Toyota considers distinctive

characteristics of each power generation method, including some examples

below:

•

Renewable power generation

•

No CO

2

emissions during power generation.

•

With costs reduced and policy support provided, increasingly introduced.

•

Although there are some factors that are making stable supply difcult,

such as differences in the amount of power generated depending on the

weather, solutions such as reinforcement of power systems and combined

use of stationary batteries are being considered.

•

Backup with other power generation methods is an issue.

•

Thermal power generation

•

Being used in many countries and regions as a stable power source.

•

To reduce CO

2

emissions, co-ring of hydrogen or ammonia is being

considered.

•

Combined application of CCS (CO

2

capture and storage), a process

of separating and recovering CO

2

in exhaust gas from plants or power

stations, is expected, though there are challenges in the selection of

proper locations, cost reduction and the development of laws.

Sustainability Data Book

2121

Case 2 Making use of low-carbon technology (reducing CO

2

emissions

intensity)

For land transport

•

Commenced use of 25-meter tandem trailers to improve transport ef ciency

and as a solution to the shortage of drivers. (From March 2022: between

Tahara and Hino, from June 2022: between Mikawa and Kyushu)

Considering gradually expanding the application while advancing negotiations

concerning the development of the operation routes.

•

Taking on new initiatives for the practical use of new technologies, including

hydrogen fuel cell electric trucks.

25-meter tandem trailer

For marine transport

•

Introduced LNG-powered pure car carriers

*2

to transport completed vehicles

from Japan to North America.

•

Added one vessel in 2021 (total three vessels).

•

Further expansion is being discussed with shipping companies.

*2 CO

2

emissions per transport unit are reduced by 25 percent to 40 percent compared to earlier diesel ships.

Initiatives in Logistics

•

To achieve carbon neutrality throughout the entire vehicle life cycle, working to improve transport ef ciency (reduce workload) and

make use of low-carbon technologies (reduce CO

2

emissions intensity) in transport of production parts, completed vehicles, and

supply parts covered by in-house logistics arrangements.

2021 Results

•

CO

2

emissions in logistics in Japan: Down 8 percent from 2018

•

CO

2

emissions in logistics overseas: CO

2

reduction activities tailored to local characteristics are being promoted

Case 1 Improving transport ef ciency (reducing workload)

Joint logistics across suppliers through in-house logistics arrangements

•

For logistics of production parts in Japan, based on the concept of retrieval system,

a principle of Toyota Production System (TPS), gradually changing the conventional

delivery system, which is arranged by suppliers, to the retrieval system, which is

arranged by Toyota.

•

By managing logistics from the perspective of the overall optimization, improving

loading ef ciency by combining the load of all suppliers and helps improve transport

ef ciency at supplier sites, thereby contributing to reduction of CO

2

emissions.

•

Gradually increasing the regions and suppliers covered by the new system, from

Kyushu to Tohoku, and to Tokai.

Relay point

Relay point

Pant

Pant

Pant

Supplier

Supplier

Supplier

Supplier

Supplier

Long lead time

Low load capacity

High load capacity

Frequent delivery

Stopping by multiple relay points

Relay point

Pant

Pant

Pant

Supplier

Supplier

Supplier

Supplier

Supplier

Direct milk run

(no relay points)

Milk run

*1

across suppliers

Concentration/

reorganization

of relay points

After kaizen (pickup system)Before kaizen (delivery system)

Loading of a truck image

After kaizen: Milk runBefore kaizen: transport by one supplier

Low load capacity High load capacity

Company A

Company A Company B Company C

*1 A delivery system in which one truck makes an ef cient circular route to pick up and deliver loads from/to

multiple suppliers

Overview Promoting Sustainability Social Governance Content Index

Environment

Policy and Environmental Management Climate Change Resource Recycling Harmony with Nature

Climate-related Financial Disclosures Based

on TCFD Recommendations

Environmental Data